As the push for digitalisation continues across all industries, data is increasingly becoming the lifeblood of modern manufacturing. When enhancing the shop floor with AI, different areas of the manufacturing process already produce and leverage huge quantities of data in a variety of ways. But the sheer volume of this data means that many optimisations and key insights are left on the table.

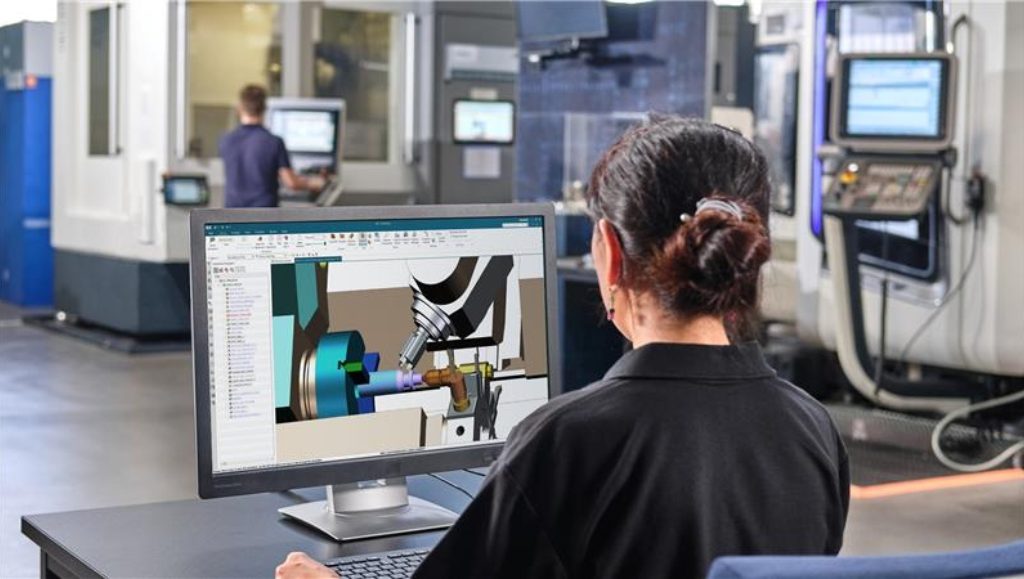

While there are many concerns around AI replacing workers, applying AI to part manufacturing doesn’t mean automating away people and processes – instead AI acts as a force multiplier, improving efficiency and productivity by augmenting existing systems. An example of this is a copilot in a computer-aided manufacturing (CAM) system which can automatically generate toolpath suggestions by analysing the 3D model of a part and interacting with complex software. Combining traditional production processes with smart data collection, AI and the comprehensive digital twin will be instrumental in achieving the next generation of data-driven manufacturing.

The need for Industrial-Grade AI

While AI offers many benefits to part manufacturing, it must also be applied with care. In the consumer space, the occasional error or hallucination might be acceptable but in industry, where vast sums of money and even lives might be at stake, any mistake in production could have disastrous consequences.

To reap the benefits of AI in industry, the AI itself must be industrial grade. Answers returned by the model must be robust, reliable and repeatable so that users don’t second guess every result. There are many steps in making Industrial-Grade AI. These include a continuous testing framework to ensure models are still giving expected results, instituting automated processes that can check for correctness, and designing software to keep humans in the loop for critical tasks. With a strong foundation in place, Industrial-Grade AI can then be leveraged in three ways to enhance part manufacturing: AI to help optimise manufacturing processes, AI to analyse manufacturing data and processes, and AI to generate manufacturing gains.

AI optimises manufacturing

Today, there are already many tasks AI can accelerate in a machine shop, or any production environment to reduce waste in labour and materials while improving production efficiency. AI is now being applied in many areas, including:

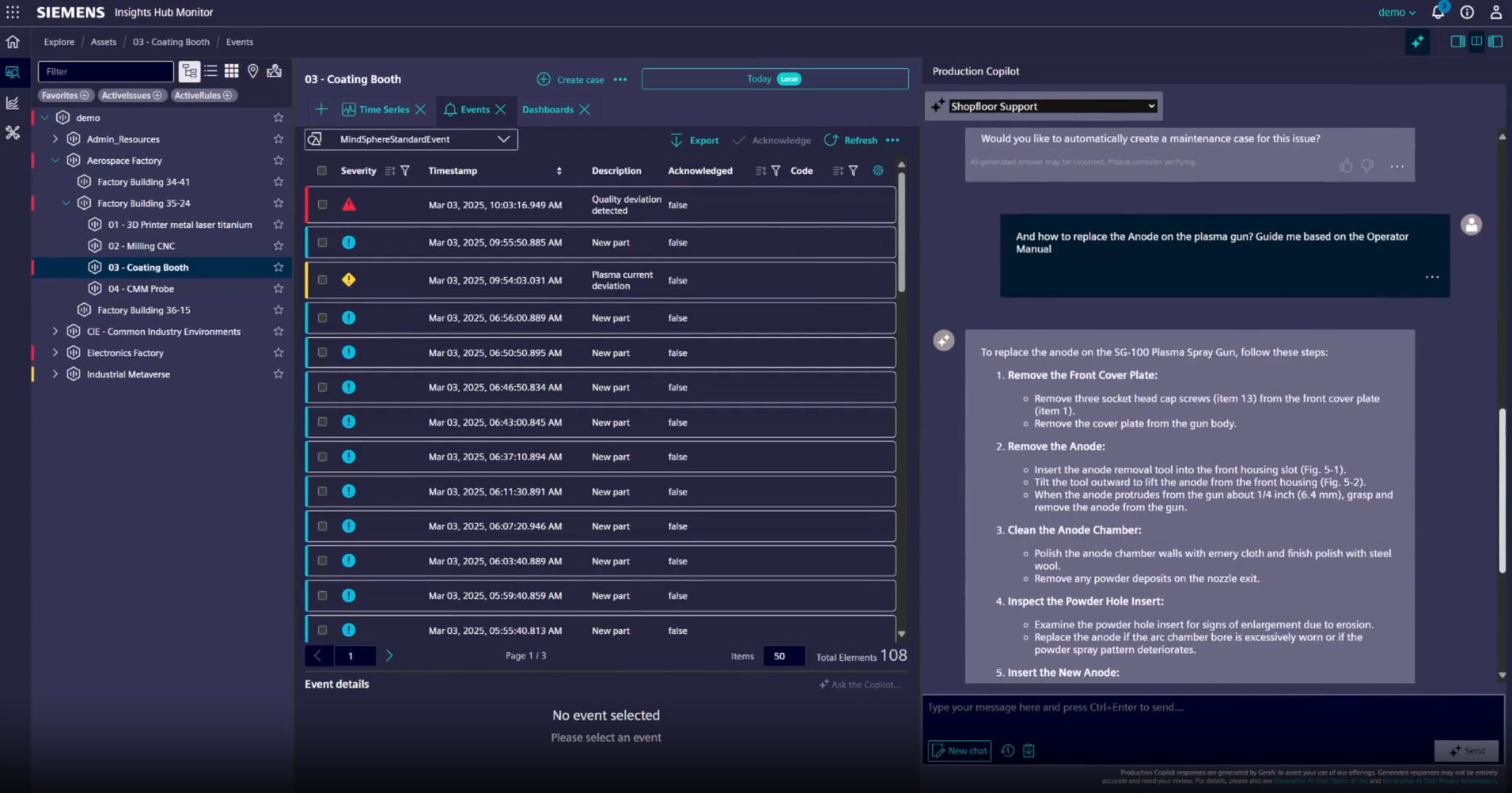

- Natural language processing (NLP) for interacting with maintenance manuals, production data and more through tools like the Industrial Copilot.

- Energy optimization to generate data-driven insights that enhance the understanding of energy conservation across production processes.

- AI-driven CAM operation editing for faster completion of jobs.

These are just a few of the ways AI is even now helping improve production efficiency. And as shops continue to invest in digitisation, the benefits of AI also will increase.

Analysing data for bigger gains

Connecting more advanced AI with shop floor, design and production data will enable optimisations of everything from workflows to ergonomics through powerful analytics. Connecting all this information within tools like Siemens Insights Hub allows AI to be applied to everything from Quality Control reports to shop floor production schedules for deeper analysis which in turn unlocks new optimisations.

One big way AI can help improve production efficiency is through predictive quality. By analysing defect data and correlating it with the production and performance data available from smart machines, it is possible to build an AI model that can identify key indicators of defects early in the manufacturing process. Catching these errors early will decrease waste of both time and materials since it minimises the risk of flaws in the final parts. For example, chatter during a machining operation results in a sub-par surface finish and reduced tool life. Chatter marks will be visible on the machined surface, often showing as wave-like patterns or regular marks. Sustained chatter can cause uneven tool wear and even tool breakage. AI algorithms can analyse data from various sensors (vibration, acoustic emission, force, current) in real-time to detect the onset of chatter. This allows for immediate adjustments to machining parameters before chatter becomes severe and affects part quality.

In addition to analysing huge data sets, AI can expedite time-consuming analysis of specialised data and use cases, such as improving ergonomics for human workers. Repetitive motions can be physically taxing, especially if they require bending or reaching in awkward ways. While there is a certain amount of intuitive analysis that any person can do when it comes to repeated motion, assessing the long-term impact can be harder. By applying an AI model, trained on ergonomics data and information about the mobility of the human body, it becomes possible to assess from a single picture the ergonomics of a particular set of movements. AI-driven human simulation can analyse high-risk scenarios effectively. This information can then be fed back into the comprehensive digital twin to quickly and easily design a workstation that is both healthy and efficient to use, with parts and tools placed in intuitive, easy to reach locations.

Generating manufacturing gains

One of the newest and most well-known forms of AI is generative AI with its unprecedented ability to converse in a human-like way. In industry, generative AI is positioned to stand as a bridge between people and technology, making complex tools easier to use. Going forward, generative AI will be a key component of no- and low-code platforms, allowing complex machinery to be programmed through NLP.

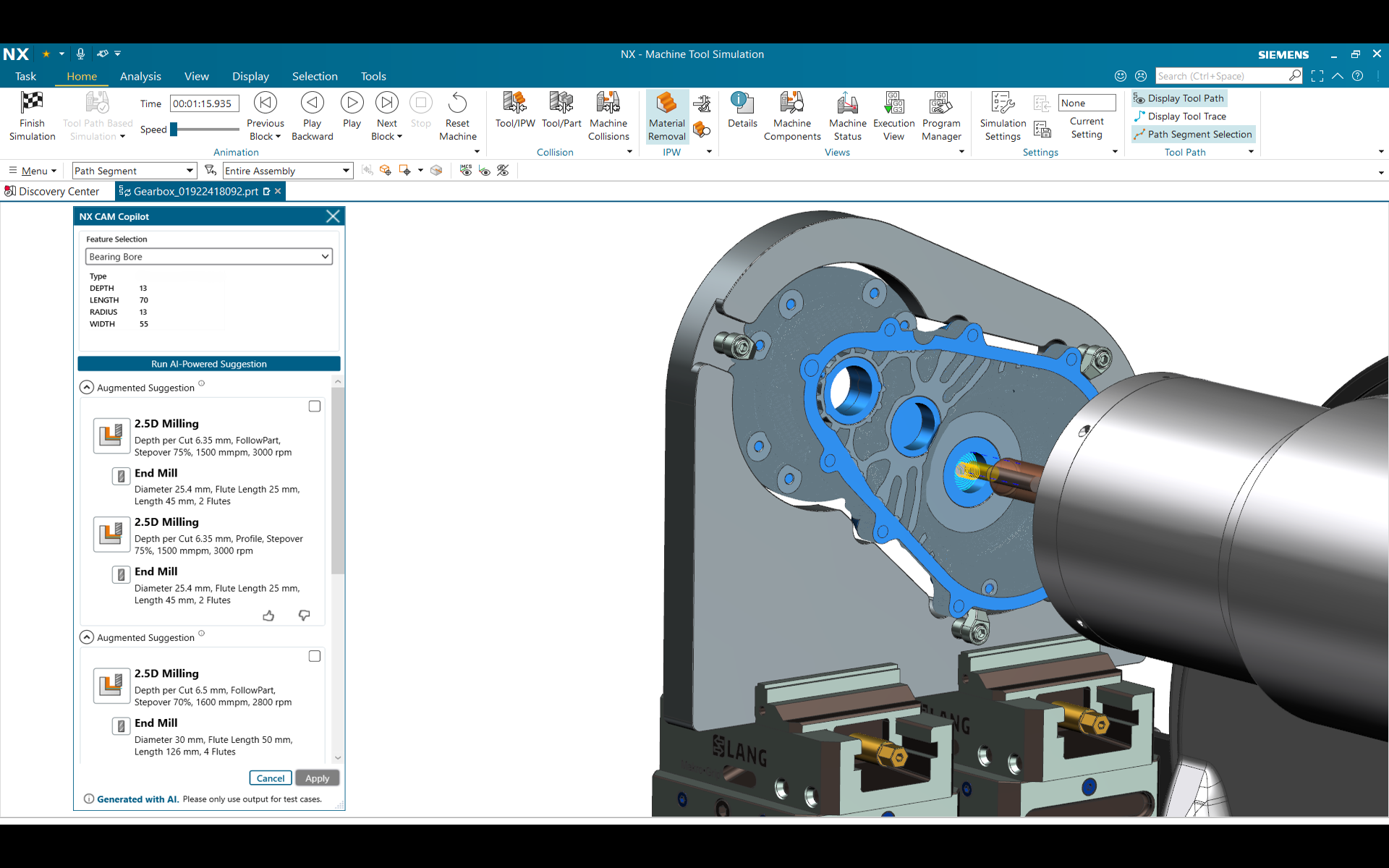

An AI-driven copilot can also significantly accelerate the creation of CNC programs, calculation of speeds and feeds, and validation of toolpaths. Today, using CAM software to go from a 3D model to usable G-code can be a complex and time-consuming task requiring significant expertise in both CNC machining and the specific software.

While the need for a human CNC expert isn’t going to change any time soon, AI, in the form of a CAM copilot, has the ability to speed up this process by making the tools more accessible while automating many of the labour-intensive manual steps. A CAM copilot can help to automate the creation of machining strategies for CNC machines, drastically cutting programming time from hours to minutes.

By simply selecting a feature on the 3D model, a CAM copilot can produce several suggested combinations of operations, tools, feed rates, etc., for user approval before automatically filling in all those values within the software. At the same time, it can be trained to understand the production machines, instantly validating if a given design and toolpath could be safely produced on a particular machine.

These type of generative AI tools can also serve as a type of knowledge base, learning from expert users and past work to use manufactured methods based on the shop’s best practices. With a strong Industrial-Grade AI deployment, this keeps proprietary knowledge secure and makes it more easily accessible to new hires and veteran employees alike, while also ensuring that valuable know-how isn’t lost as employees move to new roles or retire.

Analyse, optimise and generate with industrial AI

As the digitisation of manufacturing continues, it will become increasingly important that companies big or small are able to leverage their data to achieve quality, sustainability and efficiency goals. AI is and will increasingly be an important way of analysing, optimising and generating manufacturing improvements. With everything from simple insights to full-featured assistance, AI will be a vital part of bringing data-driven manufacturing to life as it can turn otherwise unused 1s and 0s into a goldmine for improving efficiency across the board.

To learn more about how Siemens is accelerating the path toward AI, click here.

Rahul Garg is the Vice President for Industrial Machinery at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from a 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

Rahul Garg is the Vice President for Industrial Machinery at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from a 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

For more articles like this, visit our Industrial Data & AI channel.