Siemens is the latest software provider to unveil its digital manufacturing product. Called Mindsphere, it enables manufacturers to digitalise every step of their production process from design through to delivery. Nick Peters joined the Siemens Digital Factory road show in Coventry.

Over the last year or so, The Manufacturer has reported on several digital manufacturing software solutions from companies such as IBM, GE, Microsoft, Oracle and Autodesk.

What makes Siemens’ offering slightly different from the rest of the field is that the company is not just a software solutions provider, it is also a manufacturer of a vast array of products large and small, across the globe.

That means it has had the luxury of developing its software products in-house, for its own use, well in advance of rolling it out to a wider audience, something the company believes offers them a competitive advantage.

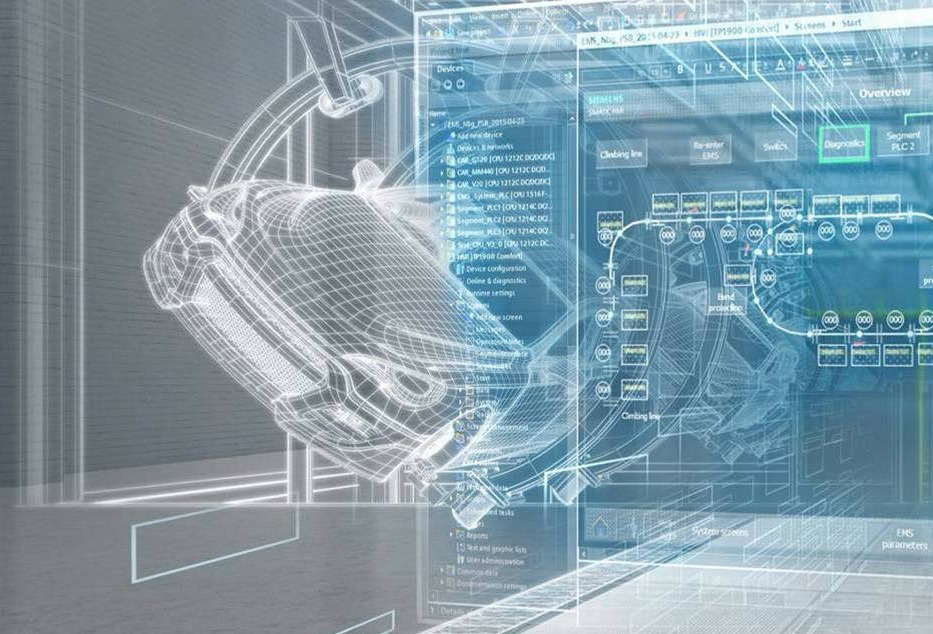

Much was made at the road show, held at the University of Warwick, of the phrase ‘digital twin’. This describes the augmented reality (AR) process by which a product can be developed and worked on virtually, before the expensive route of working on the real thing is taken.

What Siemens has come up with is a digital twin of the entire factory. Mindsphere is hooked into a factory’s ERP system – in the case of Siemens, it is its own NX-10 design and manufacturing platform – to create a closed feedback loop that sends production data back up the line to enable production to be streamlined, kinks to be ironed out, and efficiencies to be maximised.

As the factory’s digital twin absorbs more information, it develops a much clearer picture of what maximum efficiency looks like than any skilled operative could achieve, no matter how long their service.

The result is a continuous digital time and motion study to which the system automatically reacts and develops. Change on this scale has important ramifications for staffing, and it is no coincidence that this will feature prominently in the Industrial Digitalisation Review being conducted by Siemens’ CEO Jürgen Maier.

This article first appeared in the September issue of The Manufacturer magazine. To subscribe, please click here.

It is a controversial issue because, as with previous industrial revolutions, the automatic assumption is that technology will put people out of work. I discussed this, and much else, with Brian Holliday, managing director of Siemens’ Digital Factory project.

What we’re trying to showcase here is how digital design, digital make and digital services could be better exploited to create business value. We’re finding that we’re not coming across other companies that can have those digital conversations at every stage of a product lifecycle.

Is that basically because you’re a manufacturer that’s producing software that you have road tested in your own factories?

There’s no doubt we are using our own technologies, which is why we like to show our factories as an example of what’s possible. The digital enterprise thinks in digital terms about everything it does.

We would say that it starts with a data backbone, somewhere to contain all of the data associated with, for example, a product, its design, the factory, its simulation and use of the product.

Is it a closed loop of information, where the end product informs the creation of the new product?

Absolutely. In the past, in the world of computer-aided design (CAD), we’ve been able to virtualise in the design office, but now we are able to exploit powerful tools that help us think in parallel, not just about the geometry of the product, but the environment in which we’re using it.

So, we’re thinking increasingly about not just the factory and its layout, but actually how productive we can make it by simulating things. You can take the most important data, either KPIs from the factory or the design process or just big data, and then genuinely help to better inform the front end to create those virtuous cycles.

We think about low-cost connections, ubiquitous technology and an ecosystem of different partners – when these things come together to really add value with this cloud-based operating system that’s actually what’s making it much easier, the inflection point in technology to come back and create that closed loop.

It feels as if the system irons out errors and waste at every possible stage of the process, through visualisation, simulation, digitally and virtually, so that at the end of the day what you’ve got is this sort of micromanaged piece that comes out at exactly the cost that you intended it to. Is that the right way of looking at it?

If you look at any industrial process, your levers for improvement are people, process, and technology. You can do a huge amount with lean processes – and we have in our own factories, to reduce waste of energy or material itself – but that will only take you so far.

We are in a much more complex world when it comes to the design, build and use of products today. Our brains frankly aren’t big enough to tackle some of the challenging tasks of a modern manufacturing environment.

If anything, we can see the complexity growing and what’s driving that of course, is consumers who are expecting more choice, and are more demanding in terms of individualisation, delivery or localisation.

Manufacturers need to respond, and technology is a key part of that. If you simulate and virtualise, increasingly you can undertake more testing before you come to real-world cost.

You can do this in parallel so that you’re not taking perhaps 18 months to bring to market a product, as in the past. In the digital world, it could be just six. We can see technology enabling an acceleration of all of these aspects of manufacturing and therein lies an opportunity for that to be exploited.

Obviously, there are generations of older people in the workforce who may have used their inherited knowledge, experience, rules of thumb and eyeballing to refine the process.

All these skills will perhaps die out with them as they retire…are these skills being absorbed by the machines to the point where you need less skilled people on the production line? Politically, that has not gone down terribly well in some parts of society. What’s your response to that?

My response is simply that automation enables more value-adding tasks to be undertaken by humans that are appropriate to our human abilities. Appropriate automation isn’t to replace human beings, but to help make them more productive. That helps make organisations more competitive.

I see…but they need fewer skills to do tasks that their forebears would have required.

But the world is changing in so many ways that we’re seeing this not just in automation and robotic terms, but in IT as well. So yes, we need cognitive non-routine jobs that are value adding and higher skilled and higher paid. I think that’s a reality that faces the planet, frankly. I put stock, personally, in some of the research that has shown longer-term employment rise through the deployment of automation.

But yes, maybe different skills, maybe higher value. One operator, instead of undertaking one task, could oversee three in conjunction with a cobot. One operator might see the repetitive nature of what it is that they’re doing eliminated by working with a robot, but something else of added value going alongside that. Or, operators could be trained to undertake activities, not just with technology, but also contribute to a discussion in a virtual reality cave about how things could improve.

I don’t see it as replacing human activity. I see technology introduction as augmenting human activity and creating more meaningful employment, high levels of value add.

At what point do you say to smaller manufacturers who are nervous about embracing these technologies, “You’ve got to join this revolution or else you’re going to lose.” Because there’s been a very small take up, according to EEF, of 4.0 technologies among SME manufacturers in the UK.

Historically, the UK hasn’t been great at adopting automation to date, so robots is an interesting proxy for the topic of robotic and autonomous systems. In the UK, we deploy just 33 industrial robots per 10,000 workers.

In Germany, that number is 170. We are already so far behind, it is really an Achilles heel. What concerns me is that right now, when technology is enabling another significant productivity leap, we have both to catch up as well as get ahead.

I think we’ve got a role, a responsibility as engineers to better translate, to better tell the story of what’s possible, to show and not tell. That’s got to help people who are working in government thinking about policy instruments; those that are working in innovation translation; those that are working in education to think about what the careers in engineering and manufacturing might look like in the future too. I see it more as a responsibility to try and help reverse that situation.

Are you saying we need something approaching a national campaign to bring all these things together, because if we don’t we will lose out in the global race?

Potentially so. This isn’t about a technology push, this is about productivity, and we know that productivity has flat-lined in the UK from 2008, so that at headline level, the UK is behind our near neighbours, France and Germany.

This is about answering the question: what do we need to do to compete on the global stage? My personal view is technology is increasingly a part of the answer. I don’t think it’s because we can – we should. It’s now possible and we must.

Brian Holliday will be a keynote speaker at The Manufacturer Leaders Conference in Liverpool in November

Secure your place today by clicking here.