Once a tyre’s tread wears thin, you may assume its life is over. But in Stoke-on-Trent, Michelin is breathing new life into truck and bus tyres through a sophisticated, high quality remanufacturing process. Retreading is a sustainable, longer-lasting alternative to the wasteful single-use tyres that are making their way into the UK. The Manufacturer’s Tom St John went inside Michelin’s retread facility to learn more.

Michelin is a household name, and a titan of the tyre industry. Those who work in one of its 121 production facilities across the world, proudly associate the name with performance and durability. And those on the outside will no doubt think of the little, smiling, chubby fella made out of tyres. (more on him further down the page).

Key takeaways

- Extending the life of over ten million tyres goes a long way to reducing raw material use and CO2 emissions

- Quality and safety are central to Michelin’s retread process

- The influx of low-cost, singleuse tyres pose a significant environmental and industry-wide challenge

- There is strong advocation for industry collaboration, with competitors like Bridgestone, and regulatory reform to answer this challenge

FAQs

- Why is Michelin focusing so heavily on manufacturing retread tyres?

- What are the benefits of producing and buying them?

- Why is the single use tyre market causing concern?

- How thorough is the process of retreading tyres?

- What happens to the waste materials produced in the retreading process?

- What are the origins of ‘The Michelin Man?’

Group Michelin is over 130 years old. By 1927, it had established itself in the UK, and made Stoke-on-Trent its home. Which of course, is a city with its own industrial heritage — kilns, clay and craftsmanship. And just like the potteries, the Michelin plant has its own artisanal touch, albeit one focused on rubber and tread rather than porcelain and glaze.

Over the years, the Stoke plant has manufactured tyres for cars, two wheel vehicles, buses and trucks. And, just over 40 years on from arriving in Stoke, a retreading facility was built on the site. Today, the site is solely focused on giving tyres a second life through retreading. It no longer produces brand-new tyres, which makes it the company’s only retreading facility in the UK. Remarkably, as early as 1923, Michelin began to offer retread truck tyres, setting a precedent for its focus on sustainability.

The modern day retread process fuses cutting-edge technology with hands-on inspections by skilled operators. This site wants to spread the message and unite other tyre manufacturers in the fight against cheaper, single-use tyres that are flooding the UK market from overseas.

Michelin is desperately trying to convey to its customers that this alternative, while more costly, results in a significantly higher quality and more environmentally friendly product. This plant in Stoke-on-Trent is loudly leading a retread revolution, one tyre at a time.

Tread carefully

I arrived in Stoke knowing that retread certainly doesn’t mean patched-up or second-rate tyres. We visited Bridgestone in Lincolnshire last year. A competitor of Michelin, yes, but united in the retread ethos. As Andrew French, B2B Sales Director at Michelin, explained, this is a process steeped in sustainability and circular thinking. “Over the years that we’ve been based in Stoke, we’ve given a second life to over ten million tyres,” he said.

“That’s a huge sustainability win – and something the group has been committed to for over a century.” It’s easy to underestimate the significance of that number. Each retread tyre means raw materials haven’t been extracted, emissions haven’t been released, and waste hasn’t gone to landfill.

To be more specific, the retread process doubles the lifespan of truck tyre casings. Five tonnes of raw materials are saved and more than six tonnes of CO2 are prevented from entering the atmosphere for every 100 Remix tyres remanufactured.

In a world where manufacturers are focussing on sustainability as environmental regulations tighten, those numbers aren’t just impressive, they’re essential. And yet, there’s a trend in the market that’s completely at odds with this approach. “Over the last six to eight years, there’s been a big influx of budget, tier-three tyres entering the market,” explained Andrew.

“These tyres are designed for single use only. They’re not built for longevity or a second life. Environmentally, it’s a huge concern.” He continued: “That’s why we believe the multi-life offer that Michelin provides, supported by retreading, is an absolute game-changer.”

For companies like Michelin, there are several problems with the continuing influx of these tyres, many of which come from China. Two concerns are particularly key; the cost difference and the quality disparities. Both undermine the retread market, and are damaging for its long-term future.

As far as retreaders like Michelin are concerned, the problem is that good quality and environmentally sound retreads are being priced out of the market. As we’re about to find out, there is no comparison in terms of quality here. It’s cheap, short-lived tyres versus premium products designed to live again. One feeds a throwaway culture, the other a sustainable future.

The anatomy of multi-life

The plant in Stoke receives and examines used Michelin and competitor truck tyres. Once these arrive in the warehouse, they’re assessed to see whether they can be rebuilt as Remix or Encore, the two brands of Michelin retreads. The Remix line has been in place since 1968, and uses Michelin truck tyres. The Encore line, which uses worn Remix casings or competitor tyres, came in during the year 2000.

The plant has the capacity to produce 315,000 tyres per year. The retread process is a thorough and complex one, as Chrissy Peloquin, Stoke Factory Manager, explained: “There are really four major stages: casing inspection, detreading, retreading and final quality examination.”

It all starts with inspection. Tyre casings, the body of the tyre after the tread has worn down, arrive from across the UK and overseas. Each is painstakingly examined by skilled operators, both manually and using high-tech scanning equipment like X-rays and shearography machines, which can detect internal flaws invisible to the human eye “The inspection process is still very manual,” Chrissy explained. “We’re actually piloting automation in Europe right now, to make inspection better from an ergonomics and safety perspective.”

Once the casings are thoroughly examined, only the ones in a suitable condition are allowed to continue to the next stage, which is detreading. This is where the worn tread is ground away, producing a storm of black rubber crumb – a messy business, but one managed with impressive cleanliness. Chrissy smiled when she spoke about this, and it’s clearly a point of pride of her.

By her accent, you quickly realise that Chrissy is not from Stoke. She came over from Michelin’s Greenville plant in South Carolina last year, where new truck and new passenger tyres are manufactured.

“I’ve worked at other plants, including in the US. This is by far one of the cleanest sites I’ve seen. I think it’s impressive when you consider what we’re doing here – taking rubber off hundreds of tyres every day. Every crumb is collected and reused elsewhere, which is part of our drive for circularity.”

There are numerous products already being made from end-of-life tyres, such as synthetic turf, playground surfaces, shoe soles or roller wheels. And there are potential new applications which we’re yet to see. And the black tyre crumb produced from retreading can be found in sports pitches and athletic tracks, as well as industrial applications such as carpet underlay, roads and ship fenders. The process is much like the product – circular.

Quality is king

The next stage of the process sees the reclaimed casings sent for retreading. New rubber is applied, repairs are made and the whole structure of the tyre is rebuilt. “This is where automation comes in,” said Chrissy. “There is very little operator interaction with the tyre at this stage.”

The rubber and tread is cured to the tyre using heat and pressure, bonding the new tread to the old casing. And with that, a new tyre is created. However, the process doesn’t end there. Michelin’s reputation depends on quality, so naturally, the final control stage is all-important. “From the first inspection to the final stage, there’s 100% verification,” said Chrissy. “Every tyre is checked and tested. It’s the Michelin way.”

It’s a key differentiator. While some might associate retread tyres with a compromise in quality, Michelin’s relentless focus on inspection and verification ensures that every tyre leaving Stoke-on-Trent is as safe, reliable and durable as a brand-new product.

One of the final inspections involves a pressure check. The tyre is placed inside an enclosed, controlled area, just in case it goes bang. I was told this makes quite a sound, one that can be heard right across the site. As someone who doesn’t do well with sudden, loud noises, I was relieved that the tyre we were watching passed this test, and remained intact.

I asked Chrissy if customers get taken on this factory tour. “Absolutely,” she replied. “It usually seals the deal. Once people see the amount of checks and testing that one of our tyres goes through, we feel able to ask the question, ‘why consider the alternative?’” The alternative being single-use tyres that wear out quickly and end up discarded. It’s clear which path is more environmentally responsible. To say nothing of the fact that the customer is also getting a high-quality product.

The man inside the tyres

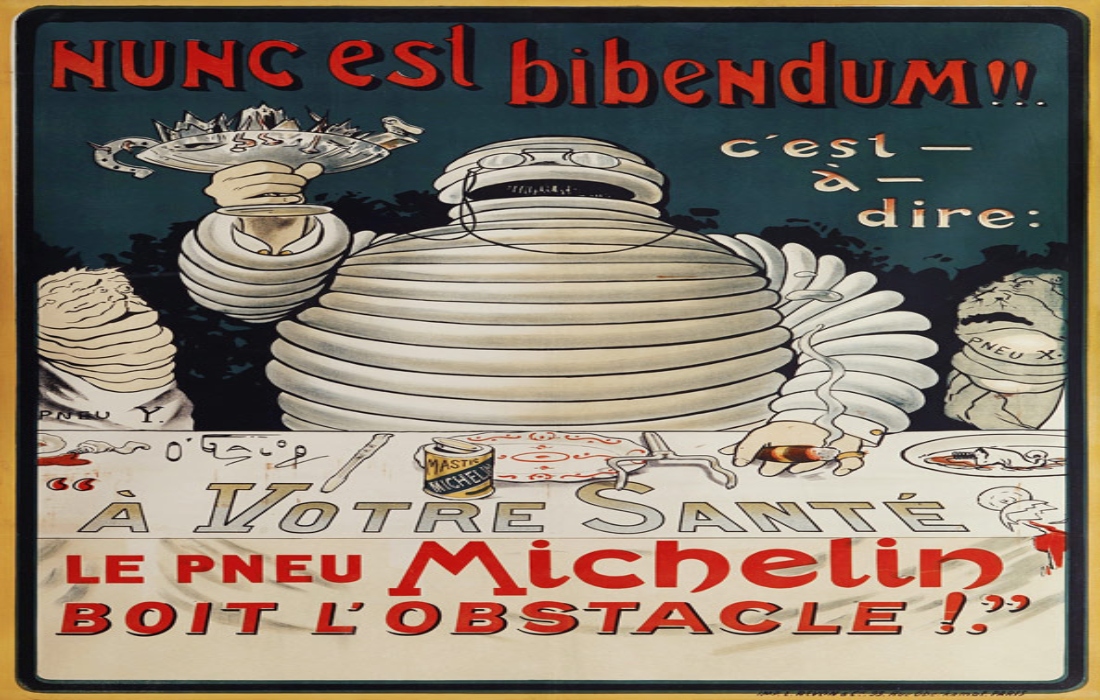

‘The Michelin Man’ is the company’s famous mascot. In an episode of The Manufacturer Podcast, our Magazine Editor, Joe, elicited a row of blank faces as he blurted out, “Bibendum.” He’d been on Google. Turns out, ‘The Michelin Man’ has a name.

Back in the late 19th century, in the early days of the company, the Michelin brothers were exhibiting their products at a fair in the French city of Lyon, when one of them noticed that if you added arms and legs to the pile of tyres they were showcasing, it would look like a man. A few years later, with the help of a caricaturist, ‘The Michelin Man’ was born. Well, the first version of him anyway.

He was actually adapted from a character in an advertisement for a German brewer. In the process, he switched from drinking beer to having the capacity of ‘swallowing the bumps in the road’ – as the early slogan went – to make the ride smoother. It was his early, slightly wilder looking years, which gave him the original name of Bibendum, from the Latin phrase ‘Nunc est Bibendum.’ Which means, ‘Now is the time to drink!’

And in many original images, like the one above, he’s holding a goblet filled with nails and broken glass. This was meant to be indicative of how tough and hardy Michelin tyres are, showing that they wouldn’t puncture easily.

Today, he’s off the booze, and he doesn’t seem to be eating nails and broken glass. I’ve got to say, he’s looking a lot happier as a result.

Built for the future

At its heart, Michelin’s retread operation is a shining example of a circular economy in action. As Andrew put it: “We’re committed to minimising impact and maximising the use of materials while they’re in service. Extending the life of tyres is crucial for reducing CO2 emissions, lowering resource consumption and improving the green credentials of both Michelin and our customers.”

As we’ve touched on, every saved casing means less raw rubber, and fewer tyres piling up in waste streams. It’s all pretty logical, and intuitively sensible. The wider challenge is getting the whole industry on board. And it’s a challenge for which Andrew has a clear vision: “There’s a lot of pressure from cheap imports, especially tier-three Chinese tyres. These are single-use, low-longevity products. It’s a real environmental setback.

“That’s why we’re working with other companies, even our competitors like Bridgestone, to push for stronger regulations and to benchmark best practices across the industry. We’re all in this together.”

Chrissy added: “Over the last three to five years there has been a greater willingness to benchmark other companies. In the past, companies weren’t interested in that, especially larger companies. We didn’t want to share necessarily.

“However, sharing best practices is the way forward, particularly when it comes to battling the tier-three Chinese market. That’s an area where we have to stick together.” This is another good example of the increased collaboration that is occurring in manufacturing. Rather than a cutthroat competition culture that may have existed in previous years. There is a problem in the tyre market that needs to be answered.

But, walking through the Stoke-on-Trent plant, there’s a welcomed feeling of optimism in overcoming that challenge. And actually, when you drill into the numbers, the UK is quite receptive to retreads – 25,000 busses are fitted with retread tyres, as well as an impressive 70% of supermarket delivery lorries.

There are also considerably less supply chain emissions when you opt for retreads; 95% of truck tyre retreads in the UK are made in the UK. Emissions are greater, and lead times are longer if you buy from China. Eight-five per cent of the worn out tyre is reused in a retread. And as mentioned already, the discarded black crumb can be used in other applications. The only metric where imported tyres win out is cost.

But as manufacturers like Michelin are pointing out, it’s also an inferior product that doesn’t have the same longevity as a Michelin retread. This means that over the whole lifetime of the product, the increase in cost is balanced out. The challenge is making customers realise this bottom line impact. Like any sustainable product or project, while you pay more upfront, your benefits are longer-lasting.

In the last issue of the magazine, we brought you the exploits of The Royal Mint’s e-waste processing – using the extracted precious metals for jewellery and sending other elements out into manufacturing supply chains. Retreading tyres might not conjure the same romance of striking gold, but the outcome is just as precious, and it’s evidence of another one of the UK’s manufacturers answering a deeply urgent problem.

One-hundred years of retreading at Michelin is proof that sometimes, the most revolutionary ideas aren’t new. They’re simply old ideas done better, at scale and for the right reasons.

KEY TAKEAWAYS

- Extending the life of over ten million tyres goes a long way to reducing raw material use and CO2 emissions

- Quality and safety are central to Michelin’s retread process

- The influx of low-cost, single-use tyres pose a significant environmental and industry-wide challenge

- There is strong advocation for industry collaboration, with competitors like Bridgestone, and regulatory reform to answer this challenge