Advanced materials, such as multiphase alloys and layered composites, are constantly being engineered to meet performance, weight and durability goals in manufacturing. However, implementing these materials requires characterising them in high resolution to understand their properties and behaviour. This forces materials engineers and quality control professionals to familiarise themselves with several specialised instruments to glean meaningful insights. Here, Dr. Anna Prokhodtseva, Product Marketing Manager at Thermo Fisher Scientific, explains how automated microscopy technology can help industrial teams keep pace.

Across automotive, aerospace and additive manufacturing, materials are becoming more complex. For example, nanostructured coatings are now standard in many applications. For all their performance advantages, such as improved strength or durability, these materials are challenging to analyse because of their intricate micro- and nanoscale features.

Researchers must record specific information about the internal structures and interfaces of these materials to assess how they will perform in their intended applications. However, obtaining thorough, high-resolution material characterisation is a laborious, technically challenging and variable process.

This is not helped by a growing skills gap. Research from Barclays Corporate and The Manufacturer has shown that UK manufacturers continue to face challenges hiring skilled workers, with 75% recording skills shortages as one of their top three obstacles to growth. Furthermore, a 2024 paper published by the International Monetary Fund noted that advanced manufacturing is among the sectors with the greatest skills gap increase.

Because of this skills deficit, many quality control and failure analysis teams lack the in-house expertise to operate advanced characterisation equipment, like focused ion beam (FIB) and scanning electron microscopes (SEM). These are required to reveal subsurface structures and generate high-resolution cross sections. However, due to the shortage of skilled operators, they are generally considered too complex or specialist for routine use in industry.

Bridging the skills gap

Thermo Scientific developed the Scios 3 FIB-SEM to help combat these challenges. It is designed for high-throughput, precise materials analysis, combining FIB and SEM technologies into one integrated system. Most importantly, it includes advanced automation features to reduce the learning curve that normally accompanies FIB-SEM systems, meaning the instrument is significantly more accessible to those with limited microscopy experience.

The ability to generate reliable, high-quality cross sections and subsurface images with little manual input is central to the Scios 3 FIB-SEM’s design. It is the first tool that offers full automation of preparation and advanced imaging of cross sections. This includes full automation of key workflows such as sample targeting, milling and imaging, reducing variability and helping maintain productivity, even when operated by less experienced users.

Finally, the Scios 3 FIB-SEM supports various configurations, including secondary ion mass spectrometry (SIMS), energy dispersive X-ray spectroscopy (EDS) and electron backscatter diffraction (EBSD) detectors. It also offers flexible configurations for lamella preparation and 3D analysis. This enables different teams to tailor the system to meet their unique application requirements, whether it’s failure analysis, quality control or materials development. Combining precision, versatility and ease-of-use, the Scios 3 FIB-SEM stands to help manufacturers overcome common barriers to advanced materials characterisation.

Automating analysis: a case study

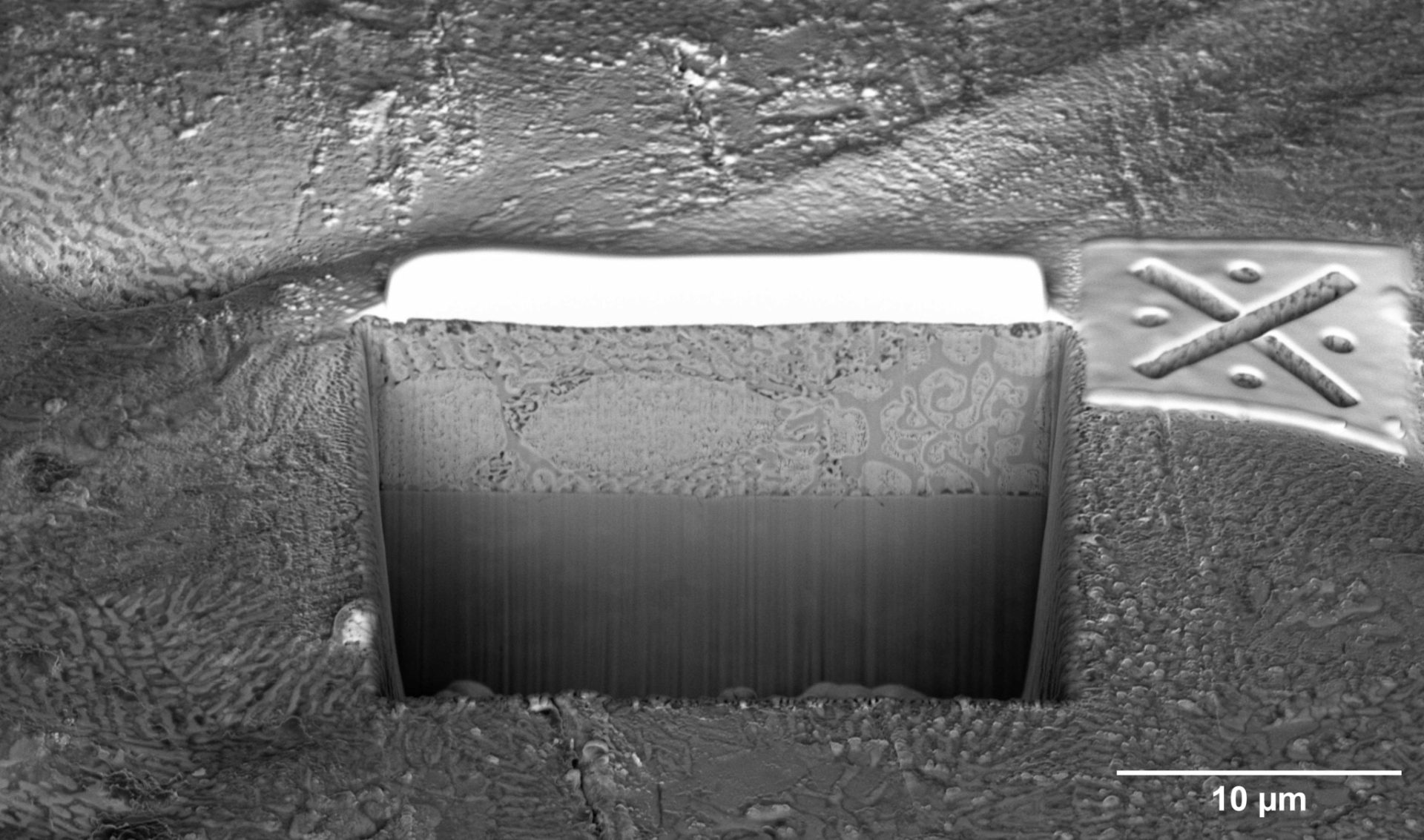

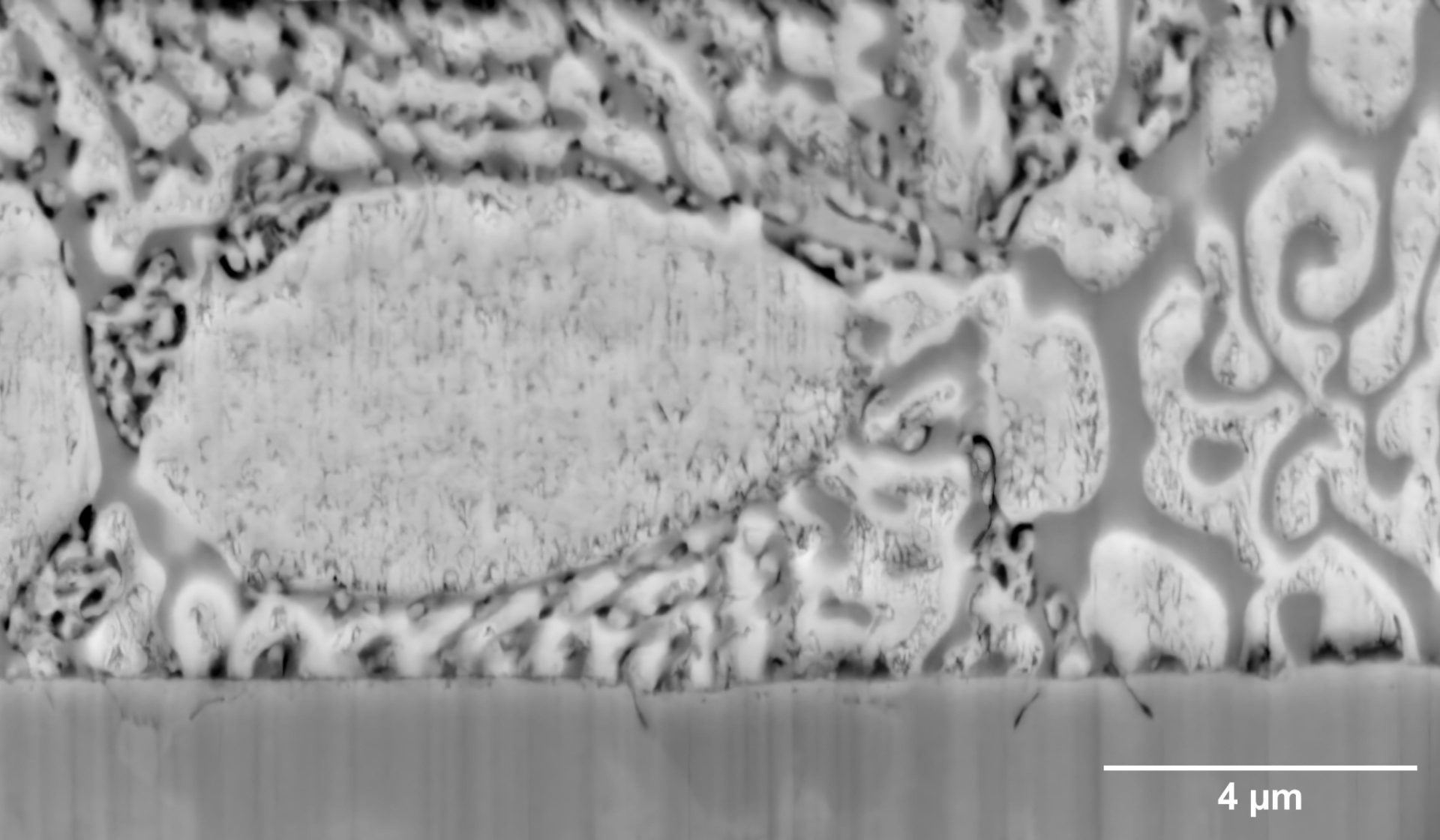

The automotive industry frequently uses zinc-based coatings to prevent corrosion on steel parts. It is difficult to conduct a thorough analysis of these coatings due to their intricate microstructures, which include fine intermetallic layers and several alloy phases.

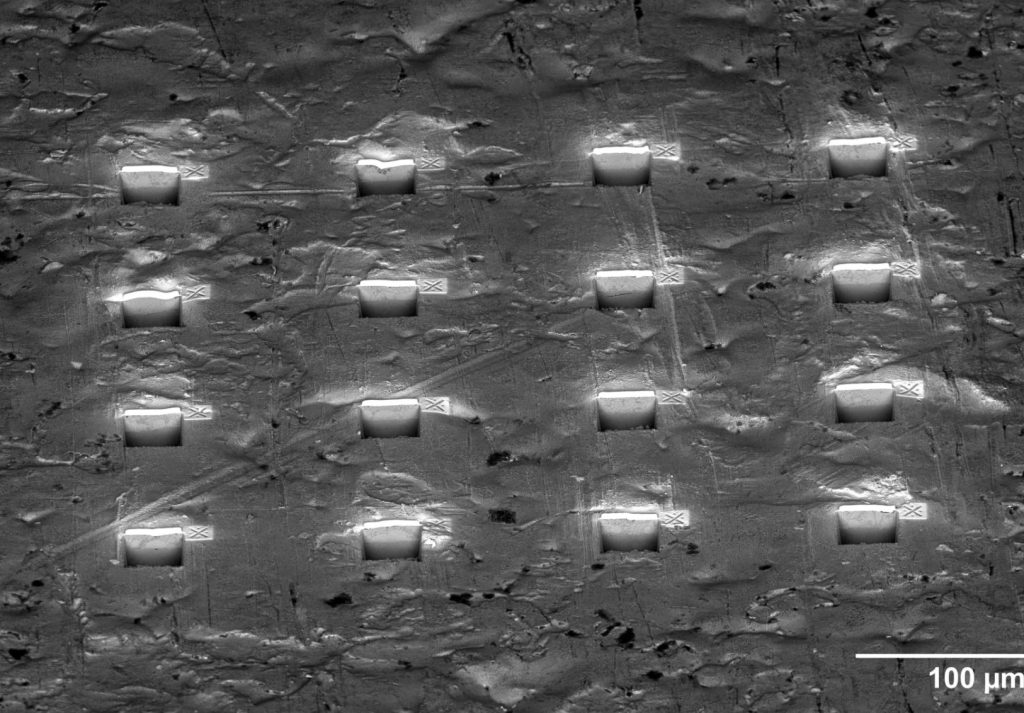

Cross sections of these coatings traditionally require significant manual labour and skilled operators to prepare and image. This procedure can now be substantially automated with the Scios 3 FIB-SEM and its Auto Cross Section (AXS) software. Users can designate areas of interest and instruct the system to mill and image these successively without constant supervision, automatically creating and imaging cross sections at multiple sites on a sample. As well as reducing the strain on operators, this automation improves consistency across samples and speeds up the overall workflow.

This is especially helpful when analysing zinc-based coatings because the feature sizes vary significantly, ranging from large primary zinc dendrites that are over 100μm in diameter to much finer eutectic phase structures of around 100nm.

In this application and many others, automated microscopy systems with integrated FIB-SEM capabilities can go a long way in helping close the manufacturing industry’s skills gap. They make advanced materials characterisation more accessible, even for industrial teams lacking specialised knowledge, by simplifying complex processes and producing precise, repeatable results.

For more articles like this, visit our Automation channel