The way manufacturers sell is changing fast. From shifting buyer demands to new competitors and redefined value, these trends will shape the future of sales.

The next five years won’t look like the last five

If you lead a sales team in manufacturing, you’ve probably noticed the ground shifting.

Your buyers are asking different questions. New competitors are appearing. And “value” in a deal now includes much more than price.

Some of these changes make headlines. Others move quietly in the background, gaining momentum. Together, they’re shaping what sales in manufacturing will look like by 2030.

Here are five major trends to keep on your radar – and why they matter for your pipeline, deals, and team.

1. The algorithmic sales era

When your CRM tells you what to do next – and is right

Scenario: It’s Monday morning. Your CRM tells you to call a mid-tier account you haven’t touched in months. The algorithm says they’re 78% likely to buy in the next 30 days. You call. They’ve just landed a major order and need new capacity fast. You close in a week.

You didn’t find that lead. The machine did.

What’s happening: AI has moved beyond pilots and hype. Sales algorithms now score accounts, set pricing, flag at-risk deals, and suggest next actions with impressive accuracy – especially when they’re working from reliable, up-to-date information. In manufacturing, this is shifting deal strategy from gut instinct to predictive models.

Why it matters: The advantage goes not to the largest team but to the one that knows when to trust the algorithm and when to override it. That means ensuring data quality, training sellers to use AI insights, and embracing machine-made plays.

Bottom line: AI adoption is accelerating, but it’s only as good as the information it’s working from. Sales leaders who prepare their teams – and their data – now will be ready to run winning plays when algorithms are calling the shots in 2030.

2. The great supply chain rewiring

Why regional networks are moving up the priority list

Scenario: It’s October 2028. You lose a contract you’ve held for 12 years. Price wasn’t the issue. Lead time wasn’t the issue. The buyer simply chose a supplier with a plant “in-region.” They even paid more for it.

What’s happening: Global supply chains aren’t vanishing, but the balance is shifting. More buyers want regional sourcing to reduce risks from pandemics, trade wars, climate events, and cyberattacks. Governments are offering tax incentives. Procurement contracts include “within 500 km” clauses. AI-driven logistics make regional sourcing faster and more predictable.

Why it matters: If you still quote lead times from a single plant halfway across the globe, you’re not just costly – you’re off the shortlist. Sales teams who highlight local inventory, regional service partners, and multi-source redundancy will win before price enters the discussion.

Bottom line: Momentum toward regional production is real, but adoption isn’t uniform. That gap is the opportunity – early movers who make regional resilience part of every deal story will win contracts before competitors adapt.

3. The decade where no deal ever ends

Why more sales are becoming long-term partnerships

Scenario: You close a £4 million equipment deal. Only it’s not really a deal – it’s a five-year uptime guarantee with quarterly reviews, revenue-share incentives, and penalties if production drops. The “sale” is now a multi-year relationship.

What’s happening: Manufacturers are shifting from one-off sales to recurring revenue. “Everything-as-a-service” is expanding beyond software. Buyers want results, not just assets – uptime, throughput, and efficiency guarantees are part of the package.

Why it matters: Even if not every deal shifts to this model, it’s becoming common enough that sales leaders need to be ready. Revenue can now depend on contract health, renewals, and expansion clauses long after closing. Forecasting requires tracking service performance as closely as pipeline deals. Comp plans, sales coaching, and customer success must align around the long game.

Bottom line:

Outcome-based contracts bring recurring revenue and operational complexity. Sales teams that master lifetime value and renewal strategy now will lock in long-term, high-margin relationships before the model becomes the norm.

4. The carbon economy

Why sustainability is climbing the buyer’s priority list

Scenario: You quote £95,000. A competitor quotes £98,000. You lose. Not for price or delivery, but because their carbon footprint was 22% lower – and your customer weighted sustainability heavily.

What’s happening: Carbon isn’t always decisive, but it’s rising in importance. Border taxes, procurement scorecards, and ESG reporting are pushing manufacturers to prove impact at the product level. Low-carbon offerings can command premiums – and sometimes are the only bids eligible.

Why it matters: More customers are asking for carbon data alongside pricing. Sales teams that can present credible, product-level sustainability information will have an edge in deals where environmental impact is a formal evaluation criterion – and that list is growing.

Bottom line: Green premiums exist, but so do budget pressures. As carbon reporting rules spread, sales leaders who build sustainability into their value story now will be ready when it becomes a must-have for their customers.

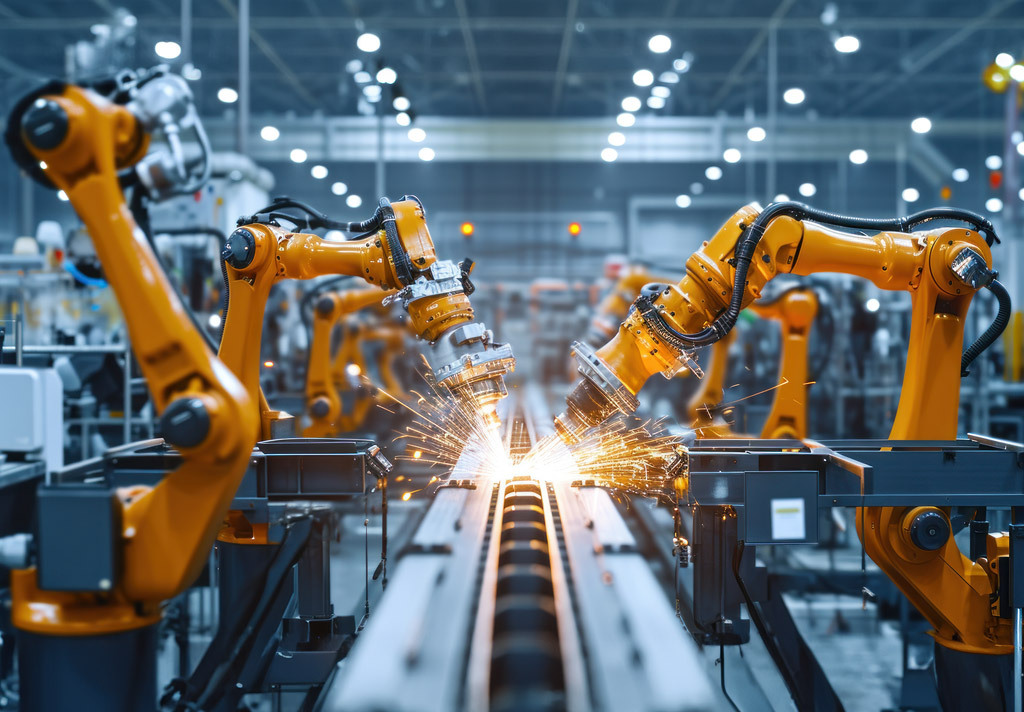

5. The post-human shop floor

From pilot projects to competitive advantage

Scenario: In 2025, only a few manufacturers can switch production overnight. By 2030, that flexibility could be decisive – letting you promise delivery in a fraction of the time and win business on speed and adaptability.

What’s happening: Robotics, AI-driven scheduling, and modular microfactories make reconfiguring production faster than ever. Today, flexibility is limited to pilots and niches, but adoption is spreading. Early movers already win customers who value fast pivots, smaller batches, and rapid responses.

Why it matters: Even if your factory isn’t fully autonomous, any step toward greater agility can become part of your sales story. Being able to promise shorter lead times, flexible order sizes, or quick spec changes can open doors to opportunities competitors can’t touch.

Bottom line: Fully autonomous factories are still rare, but the shift toward flexibility is underway. Sales teams that highlight agility now will be ready to win urgent, high-margin deals as these capabilities become more widespread.

James Frampton is Chief Revenue Officer at Sugar, brings 23+ years in ERP, CRM and ITSM. He leads sales, marketing and service, passionate about delivering next-gen CX that drives lasting customer success.

James Frampton is Chief Revenue Officer at Sugar, brings 23+ years in ERP, CRM and ITSM. He leads sales, marketing and service, passionate about delivering next-gen CX that drives lasting customer success.

Click here for his full bio.

Don’t just keep up – get ahead.

See how SugarCRM help manufacturers adapt and win.

Download SugarCRM for Manufacturers here.

For more articles like this, visit our Digital Transformation channel.