In a quiet corner of Warwickshire, far from the bustle of big-city tech, sits RYSE 3D, a production 3D printing company. This business isn’t just pushing the limits of additive manufacturing, it’s attempting to redraw the boundaries in the UK. Born from humble beginnings, this hyper-focused engineering team now 3D prints components and production tools for some of the world’s most advanced industries. Tom St John spoke with Mitchell Barnes (above), the Founder of RYSE 3D.

Unlike many additive manufacturing projects that focus on prototyping, RYSE 3D set its sights on end-use, production grade components. The industries it serves includes automotive – which is the primary focus – and aerospace, with its products found in airport security systems and scanners all over the world. Other markets include pest control, medical device development, and essentially any industries where performance and reliability aren’t optional.

The company’s core market is in hypercars, where complexity and low volume production converge to make 3D printing a good fit for the applications. “Every vehicle we touch costs between one to four million pounds,” said Mitchell. “We make all the 3D printed plastic parts on those vehicles.”

Key takeaways

- RYSE 3D challenges the conventional view of 3D printing as a prototyping tool, proving its viability as a full-scale production method

- The business was born out of necessity, but paired with technical skill and entrepreneurial persistence

- RYSE’s vertical integration shows that when you can control the full tech stack you can drive both innovation and affordability

- RYSE’s emphasis on automation and reskilling reflects an emerging trend in response to ongoing recruitment struggles

FAQs

- How did the idea of RYSE 3D come about?

- Is manufacturing really naïve when it comes to 3D printing?

- What are some of the common challenges in adopting 3D printing at scale?

- What different industries has RYSE been recruiting people from?

- What, according to Mitchell, is crucial for UK businesses to survive and grow?

Out growing the garage

Looking back on the foundation of the business, Mitchell didn’t start out with a business plan or seed funding, he started with a problem. “The whole premise of this business started by accident really,” he reflected. As a university student, Mitchell needed to manufacture models for his final-year project, but couldn’t afford to do it.

The university couldn’t assist, and traditional prototyping methods were too expensive. So, he decided to build his own 3D printer in his mum’s garage. His handy work must have been successful, because he then started selling his 3D printing services to his classmates. The initial hustle became the seed of something much bigger. “I was then able to quit my job,” he explained, “And after pulling on every contact I had, I was able to go and work in consultancy, in Formula One and other areas.”

What followed was rapid and deliberate expansion, and the birth of RYSE 3D. Which today, supports 23 hypercar programmes, employs 27 people at its Shipston-on-Stour headquarters, and has recorded impressive financial growth. “We’ve had 50 to 100% turnover growth every year,” said Mitchell. “Which is rapid growth for a manufacturing business.”

Innovation recognised

When asked to explain how 3D printing works, Mitchell paused. “That’s actually a really tough question,” he replied, “There isn’t just one kind of 3D printing.” He put it in laymen’s terms and explained that it involves making one layer of a part at a time. He gave the analogy: “Imagine slicing a bowling pin into 4,000 horizontal layers, and then printing those layers one at a time, stacking them up until the object is complete.”

The process allows for higher levels of design freedom, customisation and complexity that traditional production methods often can’t match. And indeed, there are more examples of additive manufacturing across industry. There is a need in some companies to either replace, or find an alternative, to a lot of current production technologies. However, Mitchell said that the mission at RYSE is to take the technology a step further, and create something of an awakening in UK manufacturing.

He surmised that 3D printing is still quite immature in terms of understanding, calling the industry naïve to the benefits that 3D printing brings. “Companies are using 3D printing which is good, but it’s poorly utilised,” he said. “Customers come to us, not just for 3D printed parts, but often for advice on what materials and technology they should be using.”

RYSE will support either the design and development of components or a change of specification, be that material or technology. The goal is to get the customer to the desired outcome in the most functional and cost effective way. At times parts are built purely to a specification, and in that scenario RYSE operates as any 3D printer would; it simply prints the part.

However, Mitchell believes his company offers its true value through customer support; advising the material and technology choice to get to the right solution. That advisory role is central to RYSE’s model. And while the company services highly skilled industries – clients that often know what they want to achieve – they’re not always clear on the best way to get there. RYSE steps in to guide them from idea to implementation. It’s this wider outlook on 3D printing capabilities, and a continued spirit of innovation, that earned the company national recognition.

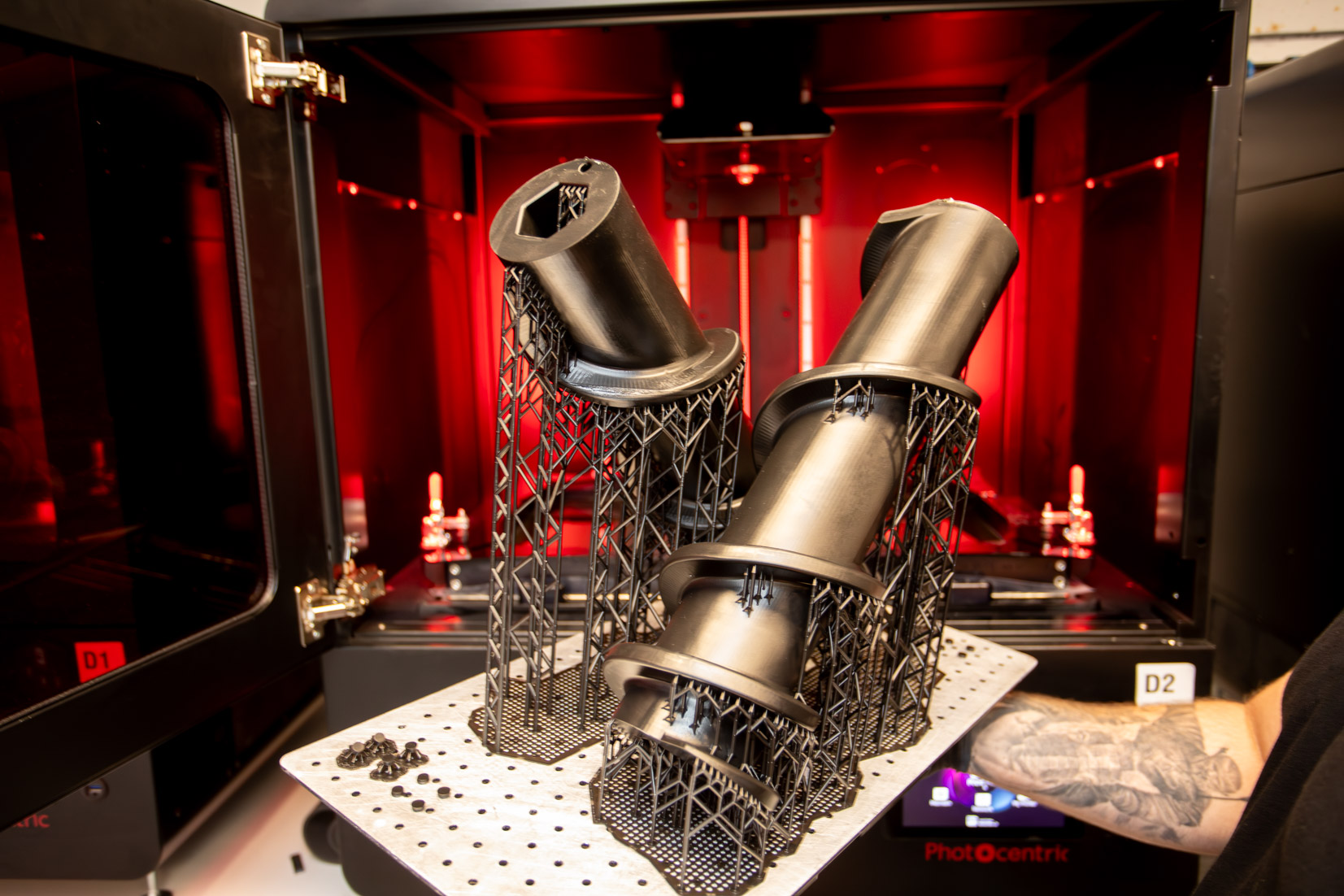

Last year, RYSE 3D won the King’s Award for Enterprise in Innovation. This was specifically for its development of 3D printed production tooling. “By looking at our own printer and material development, we were able to not just print parts, but the tools that make them,” Mitchell explained. “We’ve been able to print tools for carbon fibre, vacuum forming and injection moulding. All of them 3D printed in days rather than weeks or months.”

By enabling faster and cheaper access to production tools, RYSE has been able to help other manufacturers by accelerating workflows and lowering costs. This is all part of a wider attempt to raise the floor of 3D printing in the UK. And this is Mitchell’s mission for the company. RYSE is trying to reshore as much as it can in the UK, through tooling and through developing its own 3D printers.

Mitchell continued: “By doing this we can meet production volumes of up to 10,000 vehicle sets a year. That’s our push; we want to replace a lot of existing low volume production parts with 3D printing. We’re essentially using 3D printing to make other manufacturing technologies better.”

A new model

The company’s success is tightly linked to its ability to rethink traditional manufacturing norms. It doesn’t need to rely heavily on machine manufacturers and material suppliers. RYSE, as mentioned, brings those capabilities in-house. Innovations in the reusability of materials is a key pillar of improvement.

Pellet based 3D printers, which again, have been manufactured in-house, are able to produce parts with the same mechanical properties and performance as traditional manufacturing methods. Plant-based materials, made out of castor beans, are used to manufacture production components. The beans are grown and processed into a powder which can then be used to 3D print parts.

This can be turned into plastic components – production grade nylon – that can be found in many hypercars. “We also generate waste from support material,” said Mitchell. “We’re regrinding and reusing that to manufacturer part components. We’re trying to ensure that we’ve got as little waste as possible.” Zero waste is the overall goal, and apparently, RYSE has almost reached that target. Again, this is all aimed at making additive manufacturing in the UK accessible, scalable and profitable.

Growing smart

The speed of growth at RYSE has come with some hurdles, understandably. Like many manufacturers, it faces recurring recruitment challenges. Its location puts it at a disadvantage. Shipston-on-Stour is a picturesque market town, but not quite a manufacturing stronghold. “It’s not exactly a breeding ground for engineers,” Mitchell admitted. “We’re close to Silverstone and Brackley – motorsport valley. But there’s not a particularly big manufacturing base in the area.” Mitchell added that the company has had to be inventive when it comes to recruitment. Instead of chasing unicorn hires, a grassroots approach has been taken and talent has been picked from unlikely places.

“In some cases, we’ve hired baristas and fast food workers,” he said. “If you can follow a process, take raw ingredients and produce something at the end of it, then that’s manufacturing. We can teach the rest.” These are industries that have developed skills within people that can be transferred, nurtured and applied to a manufacturing setting.

The way Mitchell sees it, the job is about understanding process control. People can be re-skilled to use that process mindset on 3D printers. This further proves that sometimes, it’s attitude as much as anything else, that businesses are looking for in new hires. “Experience helps, but drive is everything,” said Mitchell. “A lot of people lost that during COVID and furlough. We’re trying to reignite it.”

Interestingly, university graduates aren’t being targeted quite as much, and Mitchell has shifted direction in recent years. “We’re focusing more on ex-apprentices,” he said. “This isn’t down to graduates, it’s not their fault. Universities are just so poor now in terms of educational quality – it’s more about bums on seats, and ticking as many boxes as they can. I just don’t see the quality coming out of university courses.”

RYSE is also pivoting slightly from the original recruitment plan. While early projections aimed for a team of 100, recent shifts in the UK employment landscape have forced a change in strategy. “We’re now targeting 50 to 60 staff,” Mitchell explained. “And we’re putting the rest of the investment into automation. We want to make sure the jobs we do create are secure and sustainable. That’s why we’re building a more automated, efficient system around them.”

With the increase to National Insurance Contributions coming in this year, businesses like RYSE appear to be targeting growth through productivity gains, rather than growing their workforce. In our Manufacturing Momentum Report, published earlier this year, 68% of manufacturers that responded were predicting growth. However, only seven per cent were increasing headcount. Automation, it would appear, is the catalyst of this growth, and we’re seeing increased adoption within the sector. To be precise, 55% of manufacturers are growing in this area, compared to 29% last year.

3D scaling

Mitchell was pretty clear on the broader vision for the business. “We want to be a leader in production 3D printing, parts and tooling,” This can be achieved by everything that Mitchell has touched on. It means the continued development of reusable materials, building smarter, lower cost printers and providing the UK with lower tooling costs for carbon fibre, vacuum forming and injection moulding products.

The current tooling costs often hinders production. In fact, it’s fair to say that cost hinders everything. While 3D printing has come a long way, the gap in understanding that Mitchell speaks about is almost certainly linked to the expense of buying an industrial 3D printer. And companies aren’t proficient in the technology because the cost is prohibitive. Mitchell sees this as an obvious blocker for the UK’s manufacturing sector and scaling is difficult for most businesses.

“Cost is around £70,000 to £150,000 per 3D printing machine,” he said. “So, ROI gets a bit sticky if you purchase a few of them.” However, the printers that are designed by RYSE in-house lower the entry barrier by about 90% according to Mitchell. “This allows us to scale a lot faster, and deliver production solutions to our customers without increasing cost for them. You don’t need that huge CapEx investment to get started. We don’t want to make ourselves a financial risk as a supply partner.”

Looking ahead

The journey that Mitchell and his company have been on represents a remarkable growth story, all things considered. The business has stayed profitable for its first seven and a half years. There are inevitably hurdles to overcome along the way, and RYSE exports mainly to the US, so there has been some recent disruption around tariffs.

Despite this the business is continuing to grow and last year’s Kings Award was a huge boon for the team. Its customer base makes up a lot of long-term, return business, and many of these companies are two to five years old, and continue to grow with RYSE. Mitchell gave stark but clear advice: “Innovate and invest in internal technology. That’s the only way I see survival and growth for UK businesses.”

He continued, “Irrelevant to what the government is doing, and irrelevant of the skills shortages, manufacturers need to be investing in innovation and technology to stay ahead. You cannot rely on machine or material manufacturers, or the government to do it for you. You have to remove all of those barriers by taking full control of all of it.”

This appears to be a mindset that underpins everything RYSE does. We often see manufacturing businesses hamstrung by legacy machines and processes – cautious thinking born out of fear of failure. Mitchell challenges businesses to be a little bolder, and is proving that with the right vision, tools and team, the results can be transformative. In ten years’ time, Mitchell sees RYSE as a premier production partner for automotive and other industrial companies in the UK.

He mentioned the proposed growth in automation earlier, and building on this, he said, “We’re starting to invest more in large format robotic printing. That’s been recently introduced. “This will enable us to focus more on the construction and marine industry, produce larger components and larger tooling. “So essentially, we’re looking to enhance and build on what we’ve got now, and we’re doing that through investing in our own technology, developing our own materials and our own 3D printers.”

For more articles like this, visit our Leadership section