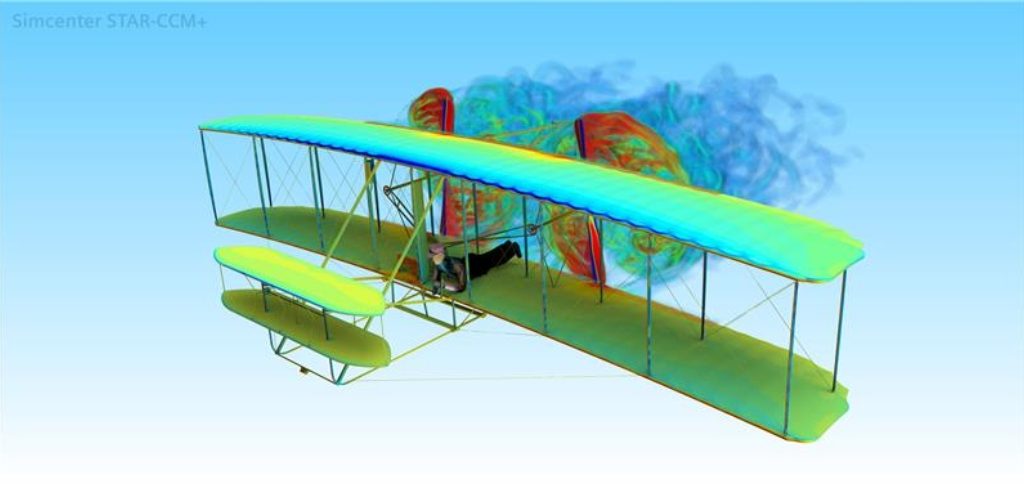

For the first 100 years after Kitty Hawk, anything that flew was largely built by hand. While the aircraft and spacecraft that followed that 12 second flight in 1903 grew into complex and expensive flying machines, their relatively low production volumes could not justify the cost necessary to automate their production. This made touch labour more affordable.

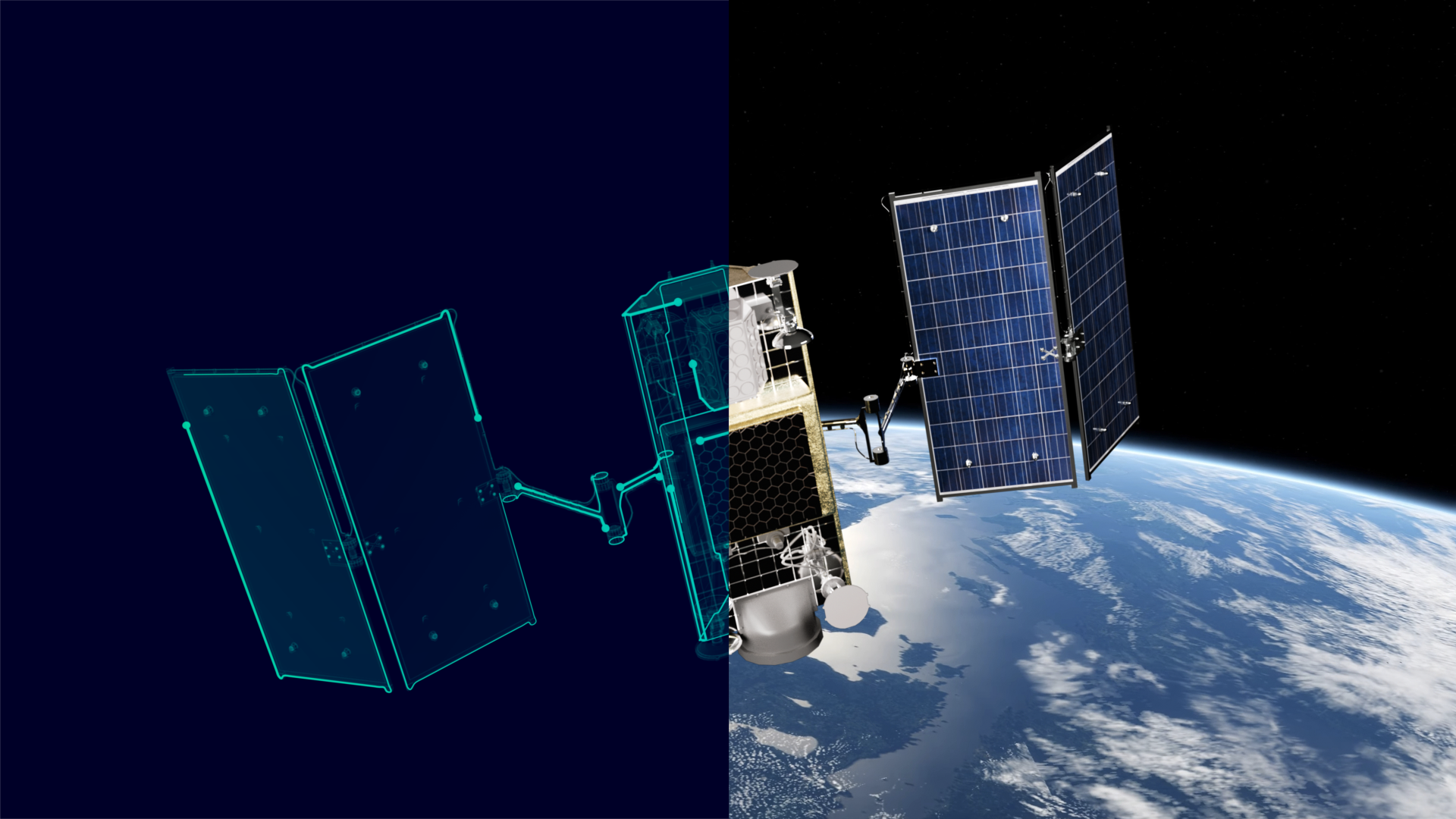

With the advent of the jet age and the space age in the mid-20th century, aircraft and spacecraft continued to grow larger and add more capabilities. Commercial aircraft were designed to carry more people and cargo. Satellites captured more and more types of data to send it back to earth. But in the late-20th century, only governments could afford to launch satellites to low earth orbit (LEO). This put limits on the number of aircraft and spacecraft that were required.

Recent innovations in autonomous flight and space launch systems, however, have significantly reduced the cost of new aircraft and spacecraft. With no pilot needed, drones can become much smaller and less expensive than crewed aircraft, making it more economically feasible to produce drones with singular functions. Meanwhile, the commercialization of space has reduced the cost to deliver 1KG to LEO from $1M in 1980 to $1K in 20201, leading to a proliferation of orbital satellites. These technological advances mean the industry produces orders of magnitude more aircraft and spacecraft today versus just a few decades ago.

This proliferation of drones and commercial satellites is changing the economics of aerospace manufacturing. As production volumes increase and costs go down, companies can no longer rely on fixed tooling and touch labour to build a profitable aerospace business.

As a result, automation has been a rising trend in aerospace factories and has become critical to profitably boosting production volume. Yet automation alone will not be enough. In order to reach companies’ desired volumes, automation must be combined with adaptive production strategies, and more importantly, digital transformation and smart manufacturing technologies. By building or refitting aerospace factories to run on interconnected data analytics and flexible, automated processes, they will not only be equipped to handle the volume and variety of new aircraft, but also, will be able to operate more efficiently than ever before.

Automation in Aerospace

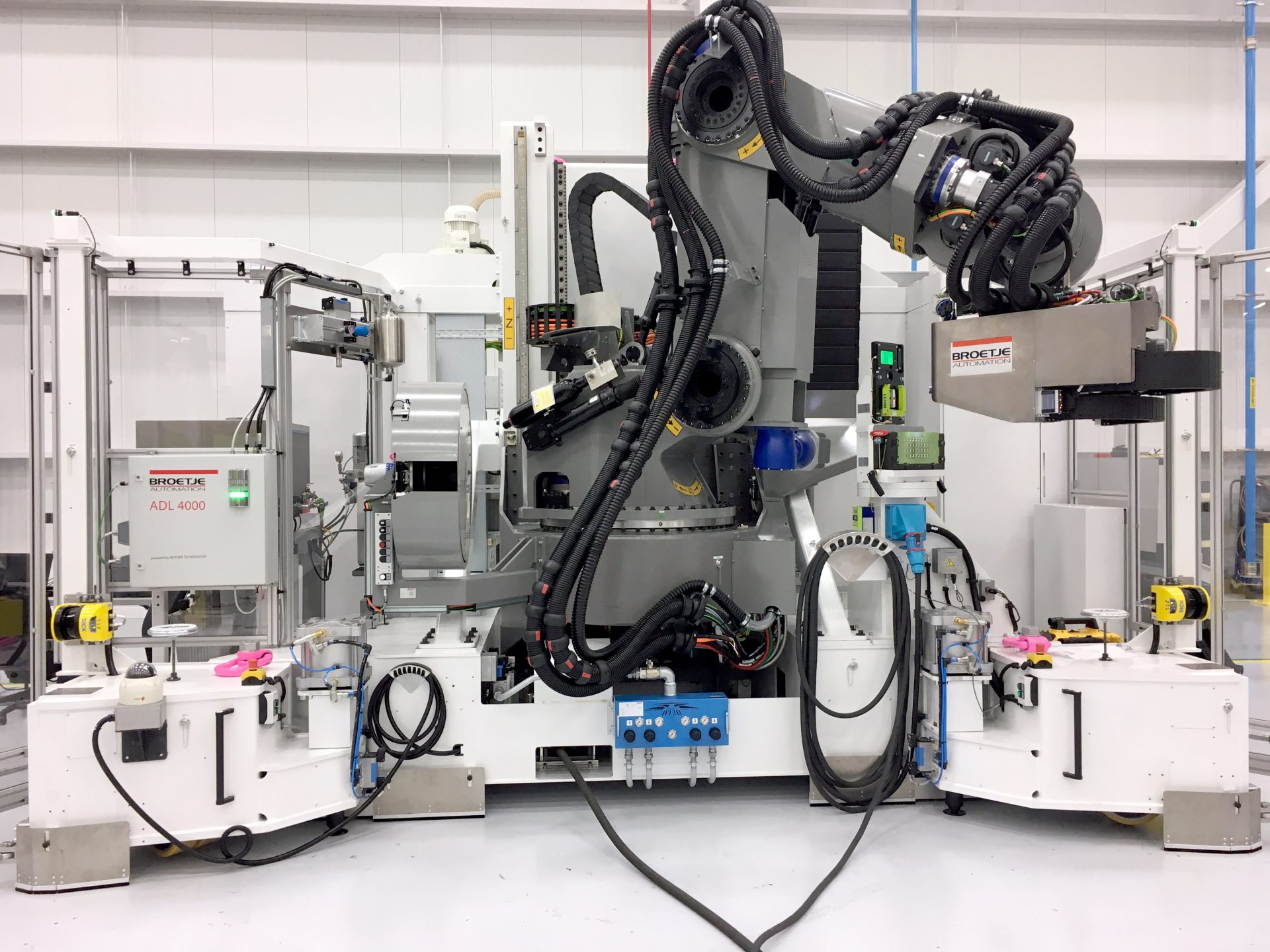

Aircraft are not the only things in aerospace becoming more automated. The production lines that make them are being automated as well. Much of the automation strategies for aerospace manufacturing, are concentrated in the machining of new parts, additive manufacturing, and the movement of materials through a factory. Offloading the responsibility of such tasks from humans onto machines, significantly decrease the time it takes to finish building an aircraft compared to factories reliant on human labour. This time will continue to decrease as automation technology continues to advance and become capable of taking on more complex tasks that previously could only be performed by humans.

Highly repetitive tasks, especially those that increase the risk of repetitive stress injuries, are prime targets for automation as it advances. For example, the alignment and riveting of metal or composite skins of an airframe has always been a mundane, routine task, but also one that could cause stress injuries for workers. Historically, it has been a complicated enough task that only humans could do it, but now there are machines being developed to take this burden off human workers, who can be reassigned to other skilled roles in the manufacturing process. Automation not only speeds up production times, but also improves people’s work environment and safety.

The Importance of Adaptability

While automation would help tackle the issue of higher production volumes for the aerospace industry’s next generation of aircraft, it may not be so proficient in tackling the variety of aircraft on its own. Historically, many aerospace components are custom-made for a particular version of an aircraft. By extension, often, the hard tooling and machines used in aerospace factories also are custom-made to produce those components. Hence, many aerospace factories are built for a select number of aircraft with little flexibility.

This can be troublesome for developing new drones and uncrewed aircraft. Many such aircraft are being designed to be modular. Even if some share the same airframe, their internal systems, electronics and other components may be designed for entirely different missions. A factory designed to assemble only a few different types of aircraft would have great difficulty producing aircraft at higher desired volumes, even if they were automated.

This is why in addition to exploring how to make their factories more automated, aerospace manufacturers must also look at how to make their facilities more adaptive. One way to do this is to make the switch from hard tooling to more reconfigurable tooling that can utilize advanced, real-time data analytics to adjust manufacturing operations dynamically to fit the needs of the aircrafts and parts they are producing. This would enable production processes to better adapt on their own to conditions that change day by day, such as desired product volumes to product variant. This would also include being able to change seamlessly between producing multiple types of drones with similar airframes, but that use different parts and systems depending on their purpose on the same line.

Data-Driven Production with Smart Manufacturing

Adaptive production’s integration of data in its operations ties it with the larger industry-shaping strategies of digital transformation and smart manufacturing. The latest iteration in the endless mission to make manufacturing more efficient with technology, smart manufacturing use the data of an entire factory and its production processes to unleash the factory’s full potential. Technologies such as robotics may have increased production volume and made human labor safer, but data is what makes everything run even better.

In addition to enabling adaptive production strategies, smart technology provides deeper insights into how production processes operate and how they can be improved. For example, the machines of an assembly line can be integrated with IT/OT sensors that monitor their activities and provide data analysis in real-time. If any machine or section of the assembly line is underperforming, engineers will be able to identify any problems and make the necessary changes to the line.

This data can also benefit other aspects of digital transformation. It can be used to improve the production digital twin, a virtual representation of a physical production system. This can replicate anything from an assembly line to an entire factory, enabling engineers to simulate any changes or new additions they want to make before carrying them out in the real world. And as the industry makes changes to its manufacturing processes to account for higher volumes, tools such as the production digital twin can help find potential errors made from those changes before they happen, saving critical time and resources that would otherwise be spent correcting them later.

Wilbur and Orville built and flew their Wright Flyer with little more than their hands. They could not have imagined how the industry they started would change the whole world in the first century of flight. Continuing that level of innovation into the second century of flight requires a whole new level of digital transformation and automation in manufacturing.

Data will be central to transforming aerospace manufacturing to reach that goal, enhancing existing automated processes while ensuring the success of new ones with the production digital twin, smart technologies and adaptive production strategies. By implementing all these strategies together, aerospace will be well-equipped and optimized to release the next generation of aircraft and spacecraft into the skies. I think Wilbur and Orville would approve.

To learn more about how Siemens solutions for aerospace manufacturing are helping accelerate digital transformation, click here.

Todd Tuthill is the Vice President of Aerospace and Defense at Siemens Digital Industries Software. He joined Siemens in June of 2022 after more than 30 years in the Aerospace and Defense industry. His engineering background is in systems design with functional engineering and program leadership roles and a strong vision for digital transformation.

Todd Tuthill is the Vice President of Aerospace and Defense at Siemens Digital Industries Software. He joined Siemens in June of 2022 after more than 30 years in the Aerospace and Defense industry. His engineering background is in systems design with functional engineering and program leadership roles and a strong vision for digital transformation.

Tuthill’s aerospace leadership career spans McDonnell Douglas/Boeing, Moog, Raytheon and Siemens, and his experience encompasses all aspects of A&D programs, including design, model-based systems engineering, software engineering, lean product development, supplier/partner management and program management. Tuthill is a passionate advocate for the advancement of digital transformation across the A&D Industry.

For more articles like this, visit our Industrial Data & AI channel.