In this exclusive op-ed for The Manufacturer, Dr. Ingo Keller, Head of Robotics at the National Robotarium, argues that, as global competition in humanoid robotics accelerates, the UK’s best opportunity lies not in building complete robots but in leveraging its precision engineering strengths to become a critical supplier of high-value components across the emerging robotics ecosystem.

Competition in humanoid robotics is intensifying rapidly. Nearly 50 companies worldwide are now actively developing these advanced machines – explosive growth from just a handful of pioneers a decade ago. Asian companies have emerged as the dominant force, accounting for more than half of all developers and commanding nearly 60% of total investment, while Goldman Sachs estimates this burgeoning market will reach £28.1bn ($38bn) by 2035.

Yet UK manufacturers face a fundamental strategic choice – compete directly with these technological giants in building complete humanoid systems, or position themselves as indispensable suppliers in the emerging ecosystem. The evidence suggests the latter approach offers far greater potential for sustainable success.

The case for component specialisation

The scale of opportunity is staggering, with major manufacturers already committing to unprecedented production scales. Tesla plans to have produced 5,000 Optimus robots by the end of this year [2025]. BYD wants to ship 20,000 humanoids in 2026. Across the globe, manufacturers are collectively aiming for production capacity exceeding 100,000 units annually.

The component opportunity within this growth is immense. Every humanoid robot requires hundreds of precision-engineered components. On average, they contain 25-30 joints, each demanding specialised bearings, actuators, sensors, and control systems. The manipulation systems – arguably the most technically challenging aspect – represent a particular opportunity where UK engineering excellence could prove decisive.

This component specialisation strategy isn’t just theoretically appealing, it’s proven. Companies that solve tactile sensing, advanced actuators, and precise control systems won’t just supply one manufacturer – they’ll become essential across the entire industry. This represents a fundamentally different business model from competing as complete robot manufacturers, where success depends on excelling across multiple technical domains simultaneously.

German engineering giant Schaeffler is already demonstrating this approach, adapting its automotive bearing expertise for humanoid applications by developing specialised, lightweight bearings that target the dozens of joints every robot requires. This capability-focused strategy illustrates how companies can leverage existing expertise while serving multiple robot manufacturers, spreading risk and building sustainable competitive advantages.

Britain’s precision advantage

For the UK, the humanoid revolution creates specific opportunities where British manufacturing heritage provides competitive advantages. While Chinese manufacturers excel at volume production of standard components, the UK can target high-value, technically sophisticated elements demanding specialised expertise.

Britain’s precision engineering sector already excels in exactly these kinds of complex, high-tolerance applications that demand deep technical knowledge rather than just manufacturing scale. From aerospace components requiring micron-level precision to medical devices demanding absolute reliability, UK manufacturers have demonstrated their ability to solve the technical challenges that others cannot.

This expertise is already paying dividends in humanoid robotics. Companies like Touchlab, based at the National Robotarium, are developing advanced tactile sensing technology that gives robots the ability to ‘feel’ – crucial for the manipulation tasks that current humanoids struggle with. COVVI represents another success story, leveraging years of prosthetic engineering experience to create interoperable robotic hands that help hundreds of users while developing the precise control systems humanoid manufacturers desperately need.

The lesson here is clear. UK manufacturers should focus on capability rather than application. Instead of building complete robots for specific use cases, successful companies will develop technologies that multiple robot manufacturers need. This approach leverages existing UK strengths while avoiding direct competition with well-funded complete system manufacturers.

The narrowing window

However, the opportunity to establish a position in humanoid supply chains is time-sensitive. Current humanoid manufacturers, focused on proving their complete systems work, remain open to component partnerships. But if history tells us anything, this openness won’t last forever.

As production scales increase and partnerships solidify, entry barriers will rise exponentially. The automotive industry provides a relevant proofpoint. Today’s tier-one suppliers like Bosch and Continental established relationships during the sector’s formative years, creating positions that proved remarkably durable across decades of technological change.

The same pattern is emerging in humanoid robotics. Early movers in component specialisation will secure the relationships and expertise that become increasingly difficult to replicate as the industry matures. However, seizing this opportunity requires more than individual company initiative – it demands recognition from government that robotics deserves dedicated strategic focus as a cornerstone of UK industrial policy, not merely as a subset of broader AI initiatives.

The future blueprint

This transformation could spawn entire regional clusters of excellence, each specialising in different aspects of humanoid technology. Imagine precision bearing centres in Wales, tactile sensing hubs in Scotland, and advanced actuator specialists in the North of England – creating a distributed network of expertise that no single country could replicate

This isn’t just about supplying today’s humanoid manufacturers. As robotics technology matures, the winners will be those who’ve built deep, specialised knowledge that becomes the foundation for next-generation innovations. UK companies positioned as essential component suppliers today will be perfectly placed to drive tomorrow’s breakthroughs in human-robot interaction, autonomous decision-making, and adaptive manufacturing.

As such, the choice facing Britain is clear: become a footnote in the robotics revolution or write its next chapter. By focusing on what UK manufacturing does best – precision, innovation, and technical excellence – rather than trying to match the scale of complete system manufacturers, Britain can secure a central role in the most transformative technology of our time.

The robots are coming, so let’s build them here.

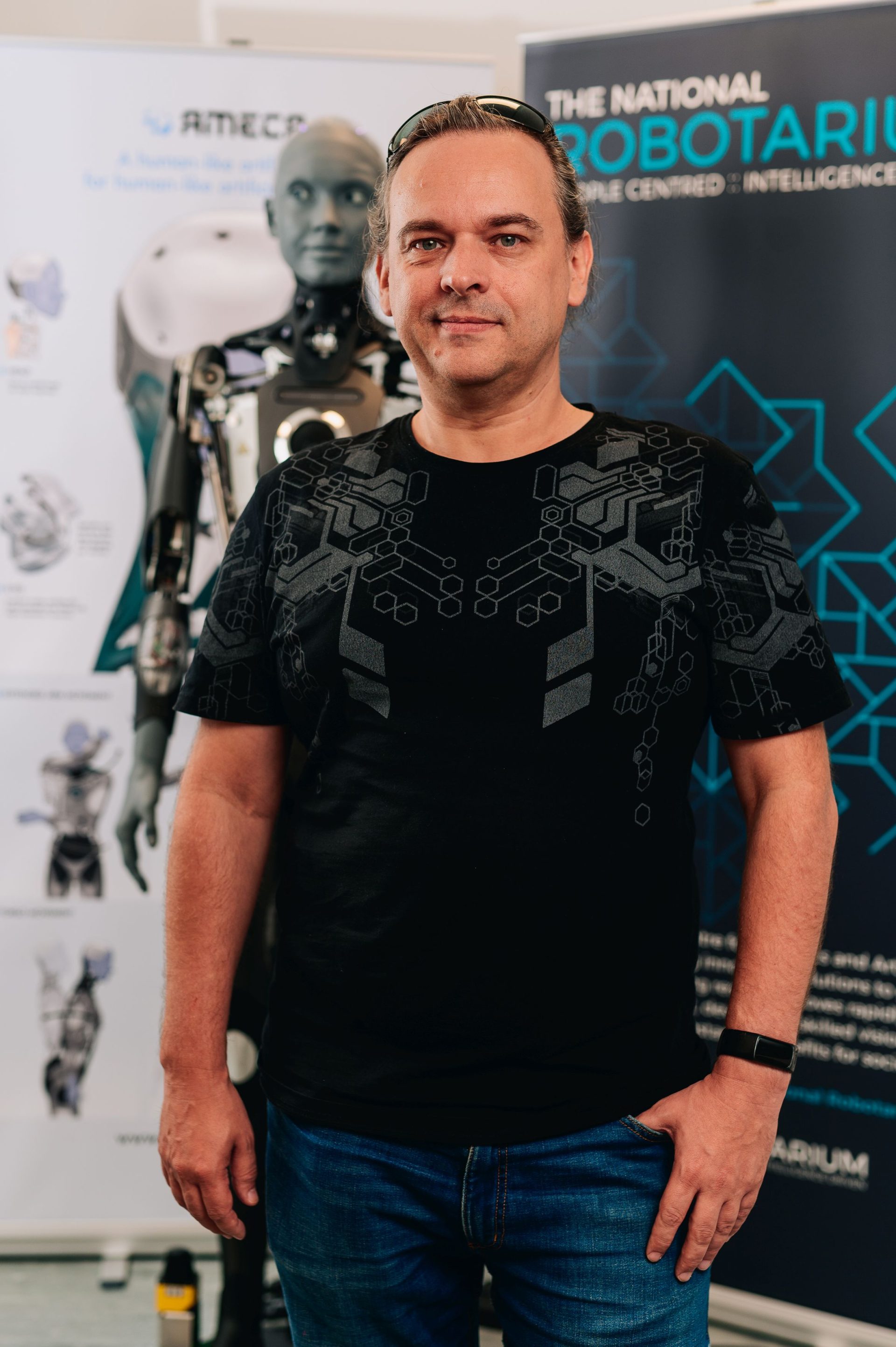

About the author

Dr Ingo Keller is Head of Robotics at the National Robotarium, where he leads the development of cutting-edge robotics solutions for real-world challenges. With over 20 years of experience spanning software, AI and robotics engineering, Ingo has co-founded multiple start-ups and brings deep expertise in taking emerging technologies from lab to market. His mission is simple: getting more robots “out of the lab and into the wild” by working directly with industry to develop safe, practical robotics that can be seamlessly integrated into society.

For more articles like this, visit our Automation channel