In this exclusive op-ed for The Manufacturer, Nigel Clarke, CEO at Morgan Innovation & Technology argues that while automation enhances efficiency, British manufacturing’s success depends on human ingenuity, adaptability, and innovation—especially in high-stakes, rapidly evolving scenarios.

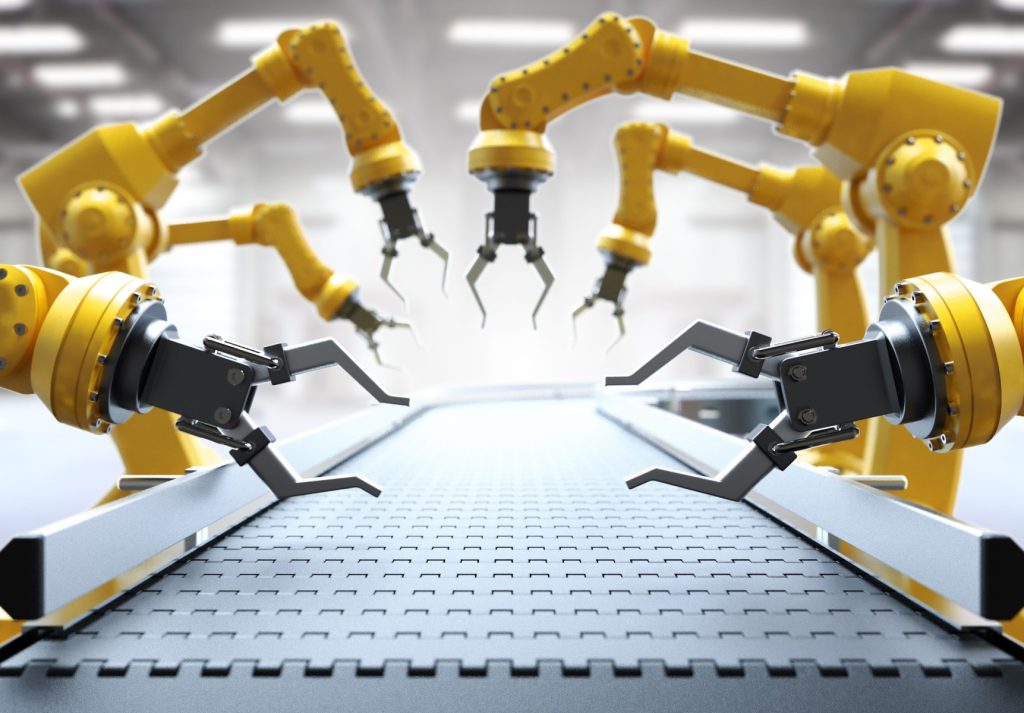

Automation and robotics might dominate today’s headlines, but there’s still something crucial that technology can’t replicate; human judgment, intuition, and adaptability. British manufacturing, built as it is on a legacy of innovation and craftsmanship, should bear this in mind when contemplating the future. Robots are undoubtedly useful, but they’re far from the full story.

Let’s look at that hottest of manufacturing topics, reshoring, for example. Bringing manufacturing operations back to the UK is about responsiveness, agility, and rapid problem-solving and it can’t be achieved solely by installing advanced robots or automated assembly lines. SMEs – the lifeblood of the British economy – have consistently shown incredible flexibility, reacting quickly to disruptions in global supply chains. They’ve achieved this by relying on smart, adaptable teams who understand that genuine innovation frequently involves thinking on their feet and often outside the box, something that robots aren’t yet equipped to handle effectively.

This need for human ingenuity cuts across multiple industries, from medical devices to defence and consumer goods. Consider the Pfizer COVID-19 vaccine rollout: Morgan Innovation & Technology was contracted during the pandemic to manufacture 6,000 critical tracking devices a week. These devices ensured the vaccine’s safe distribution globally and required Morgan to adapt our existing setup overnight giving us the ability to ramp up quickly and reliably. Stringent quality control and a strategic pivot depended heavily on human oversight and problem-solving, and I honestly doubt that an automated system alone could have achieved what we did.

Another example can be found in the automotive industry. During the height of the COVID-19 crisis, Jaguar Land Rover became part of the Ventilator Challenge UK consortium, pivoting rapidly from producing luxury cars to essential ventilators. This dramatic switch in production lines required not only technical reconfiguration but significant creativity, adaptability, and problem-solving skills from their human workforce. Such a radical shift demonstrates precisely why automation alone can never fully replace the irreplaceable human factor.

Similarly, JCB stepped forward during the same ventilator challenge, quickly transitioning from building heavy construction machinery to producing casings for ventilators. This rapid repurposing was achieved not by machines alone but by teams of skilled workers demonstrating remarkable agility, ingenuity, and coordination under extreme pressure and tight deadlines.

Of course, the role of automation shouldn’t be understated. Robots deliver consistency, efficiency, and enhanced safety, particularly for repetitive or hazardous tasks. However, the future of manufacturing shouldn’t be framed as a battle between humans and robots; it must be about harnessing robotics to complement and amplify human capabilities. The most successful factories blend advanced machinery with skilled human teams who can manage exceptions, adapt processes quickly, and innovate continuously.

Investment strategies therefore need to reflect this blended approach. Allocating resources towards workforce training and nurturing creativity can yield significant dividends, often surpassing those gained from simply acquiring more machinery. The UK’s educational and apprenticeship programmes should prioritise technical competence but ally it with critical thinking, problem-solving, and creative innovation skills. British manufacturing needs technicians capable of operating sophisticated equipment, but more importantly, it needs visionaries who can maximise technology’s full potential.

Looking at this in greater detail, sustainability, now non‑negotiable for modern manufacturing, can’t be reached by automation alone. It demands creative problem-solving, ethical judgement, and long-term strategic innovation and these remain areas where humans truly outperform machines.

Take the Siemens Industrial Copilot at Thyssenkrupp: engineers use generative AI alongside their experience to code and optimise battery‑production machines, reducing waste and avoiding overuse of materials, and cutting downtime. The human‑AI pairing tackles sustainability head-on in real time, the AI mines data, the humans interpret nuances and make judgement calls. That kind of synergy, data-driven efficiency with real human insight, is exactly what’s needed to meet climate, resource, and ethics goals where robots alone simply can’t.

There’s another aspect that’s often overlooked and that’s in the field of high-value, low-volume manufacturing. The UK has countless SMEs producing specialised equipment and critical products in relatively small quantities, maybe in the tens, hundreds, or low thousands each year. Many of these items significantly impact lives, particularly in healthcare settings. At Morgan, a substantial part of our manufacturing involves exactly this kind of production, blending precise manual assembly, careful calibration, and targeted automation. There’s no way we could automate everything and often in these situations full automation just doesn’t stack up financially. Manual labour remains a cornerstone because it’s genuinely the smartest way to deliver specialised, impactful products.

At Morgan Innovation & Technology, I’ve seen firsthand how blending robotics with human expertise creates genuine breakthroughs, particularly when agility and rapid problem-solving are paramount. Throughout our decades in manufacturing, it’s always been clear that while machines make things efficiently; people make things that matter.

When I look forward, I can see that the success of UK manufacturing hinges less on how automated factories become and more on how intelligently we integrate advanced technology with human expertise. Robots might handle tomorrow’s assembly lines, but it will always be people who set direction, solve unforeseen problems, and drive meaningful innovation. British manufacturing’s strength has always been its ingenuity and adaptability and by understanding the limitations of robotics and celebrating the essential role of human input, we can retain a competitive place on the global stage.

To secure the industry’s future, we must recognise and reinforce this fundamental truth: manufacturing isn’t really about the products we make, it’s about our people, their ideas, and their capacity to adapt and innovate and I believe that’s a future genuinely worth investing in.

About the author

Nigel Clarke, CEO at Morgan Innovation & Technology.

Nigel Clarke, CEO at Morgan Innovation & Technology.

As CEO of manufacturing firm Morgan Innovation and Technology, Nigel leads a dedicated team of experts in developing new products that have a significant positive impact on society. His company works with highly talented inventors to develop their products, supporting them with expertise in electronic engineering and providing services from R&D through to bringing products to market.

Over the years they have launched a range of products from pain relief machines to anti-snoring devices and sophisticated diagnostic technologies. Morgan IAT have won a range of awards for innovation in manufacturing over the years including two highly prestigious Queen’s Awards.

For more articles like this, visit our Automation channel.