Embro’s smart heating textiles are setting a new standard for intelligent thermal management in the automotive, medical and aerospace sectors.

A new era of smart heating systems for OEMs

Lightweight, mobile and sustainable design trends will shape the next generation of OEM products, and traditional heating systems will have to face these challenges. Textile-based heating elements are the answer: smart, flexible and sensor-enabled systems that allow OEMs to create intelligent thermal features directly in the fabric.

These textile innovations are more adaptable than conventional heating technologies and support the growing demand for intelligent system integration. Embro’s flexible heating and sensing textiles are a strategic leap forward for design engineers working in the automotive, medical devices, aerospace and wearables sectors.

Why smart textiles matter to OEMs

When engineers think of heating systems, they often picture wires, foils or silicone mats. However, in space-constrained or ergonomic products, these traditional solutions add weight, complexity and limit design freedom. Textile-based heating offers an alternative: lightweight, conformable and scalable.

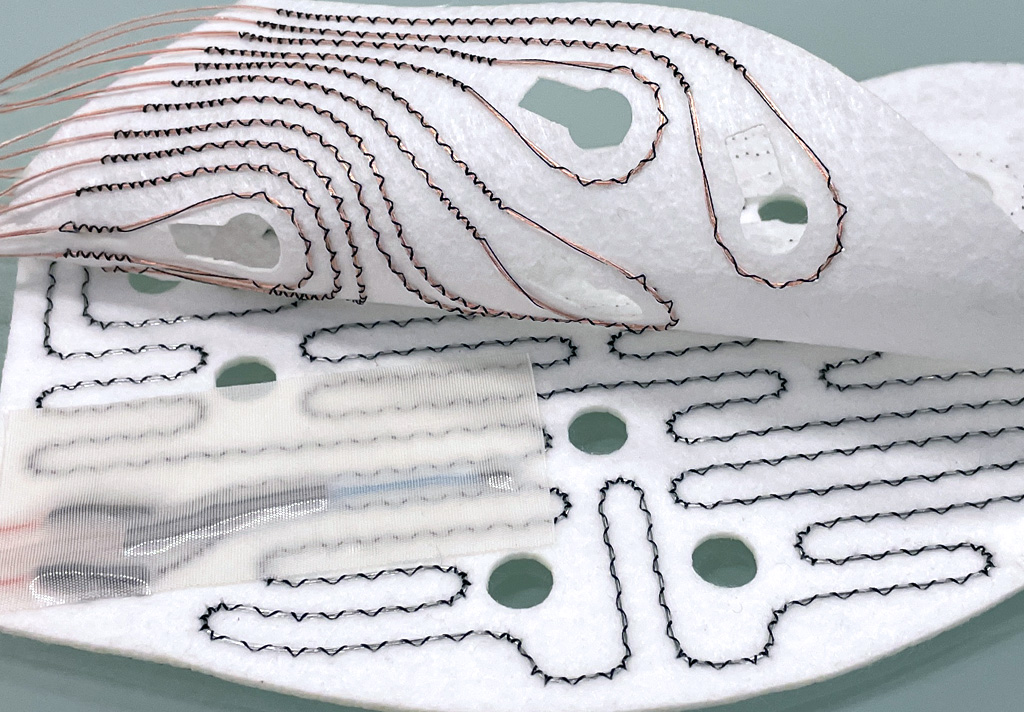

Embro’s textile heating systems use precision-applied conductive threads integrated into flexible carriers. The result is a custom heating element that can be stitched, laminated or bonded into a product without sacrificing its original design and without needing bulky components or separate sensors.

From heating to sensing – all in one layer

One of the defining innovations behind Embro’s technology is the seamless combination of heating and sensing functions. Conductive threads are configured to provide heat and measure key parameters, such as temperature, strain or pressure.

For OEMs, this means fewer parts, simpler assembly and greater reliability. Applications include:

- Battery pre-heating with integrated temperature monitoring

- Medical rehabilitation aids with real-time feedback

- Wearables that adapt to motion or climate conditions

- Aerospace and interiors where every gram counts

Technical embroidery as enabler

The foundation for these smart systems lies in a production method known as technical embroidery. We use CNC-controlled embroidery machines to apply functional threads to textile substrates with micron precision. Unlike traditional lamination or extrusion, technical embroidery allows design flexibility, repeatability, and customisation.

Key benefits include:

- High precision in functional layout (e.g. zonal heating)

- Capability to combine heating and sensor threads in one process

- Compatibility with a wide range of carriers and laminates

- Adaptability to 2D and 3D surface geometries

Applications of smart heating textiles across industries

Embro’s heating and sensor textiles are already in use in multiple industries:

Automotive

Textile heaters are used for seat heating, steering wheels, door panels, and battery pre-heating. These systems now feature integrated sensors that detect occupancy, material strain and temperature levels, which boosts safety and efficiency.

Medical technology

Flexible heating elements are a good choice for warming therapy or rehabilitation products. Integrated sensors track surface temperature and skin contact, enabling patient-specific control.

Aviation & aerospace

Textile-based heating is the answer to managing micro-climates in cockpits and cabins. It provides intelligent thermal feedback loops without adding unnecessary weight. These systems are suitable for aerospace interiors where comfort and weight are vital.

Wearables & outdoor equipment

Smart heating textiles are used in sportswear and outdoor clothing to deliver active thermal control, comfort and energy efficiency. Real-time feedback ensures responsive warmth and extended battery life.

Damage sensing: smarter protection in transit and structures

In addition to comfort and functionality, textile systems also play a vital role in damage detection.

For transport and logistics, Embro develops sensor-integrated fabrics that monitor mechanical stress during transit. These safety textiles can detect pressure changes, potential leaks and impacts, providing real-time alerts and enabling fast responses. The result is improved traceability and better insurance outcomes.

In fibre composite applications, such as battery housings, embedded sensor threads can identify early signs of delamination, cracking or material fatigue. The system monitors changes in resistance, enabling predictive maintenance and enhancing structural integrity, particularly in high-risk environments such as EV battery systems.

The OEM advantage

Embro’s solution offers clear competitive advantages for engineers and decision-makers:

✔ Lower BOM complexity: One textile, multiple functions

✔ Energy efficiency: Zoned heat only where needed

✔ Faster time-to-market: Pre-tested textile modules

✔ Lightweight: No bulky housings, minimal impact on mass

✔ Custom engineering: Adapted for your process and compliance needs

✔ Scalable production: From prototypes to serial supply

✔ European quality: Custom heating elements made in Europe

Built in Germany, engineered for the world.

Embro’s custom heating elements are developed and manufactured in Germany to meet the specific requirements of original equipment manufacturer (OEM) partners. The company supports its clients throughout the product lifecycle, from feasibility studies and prototyping to small- and large-scale production. Thanks to its team’s interdisciplinary background in textiles, electronics and manufacturing, Embro is a unique development partner in the field of smart textiles.

Let’s build the future of smart heating together!

To find out more or to discuss your next innovation project, get in touch with the Embro team at info@embro-tech.com or visit https://embro-tech.com. We are your partner for custom heating elements manufactured in Europe.

Markus Flechsing, CEO of Embro GmbH

Markus Flechsing, CEO of Embro GmbH

With over 15 years of experience in technical embroidery and textile electronics, he is passionate about redefining the role of textiles in modern engineering.

For more articles like this, visit our Innovation channel.