A shift from a linear economy, where products are made, used, and discarded, to a circular economy that keeps materials in use for as long as possible, is fast becoming one of the biggest challenges for the manufacturing industry.

But it also presents a significant opportunity. The potential impact of circular manufacturing, for the planet, for supply chains and for individual businesses, is huge. Remanufacturing is a critical element of this, by extending product life spans through methods to deliver high-integrity components that meet, or exceed, their original specifications – offering more value than simply recycling and reusing the core materials. However, the industry currently faces challenges due to a lack of product data, which results in cost-intensive reverse engineering and prevents businesses from scaling the circular economy.

In parallel with the sustainability challenge, businesses are also anticipating the impact of impending EU legislation, such as the introduction of digital product passports (DPPs). These are essential if businesses want to keep trading within the EU market and while it requires a new way of working, with the correct data and information included, these could become a key enabler of remanufacturing in the years to come.

The need for digital product passports

The EU Ecodesign for Sustainable Products Regulation will require Digital Product Passports (DPPs) for specific product categories from 2027, starting with batteries and textiles, before being expanded to include a range of items such as furniture, detergents, chemicals, paints, tyres, iron, steel and aluminium. Products that fall under the regulations can only be sold in the EU market if a DPP is available.

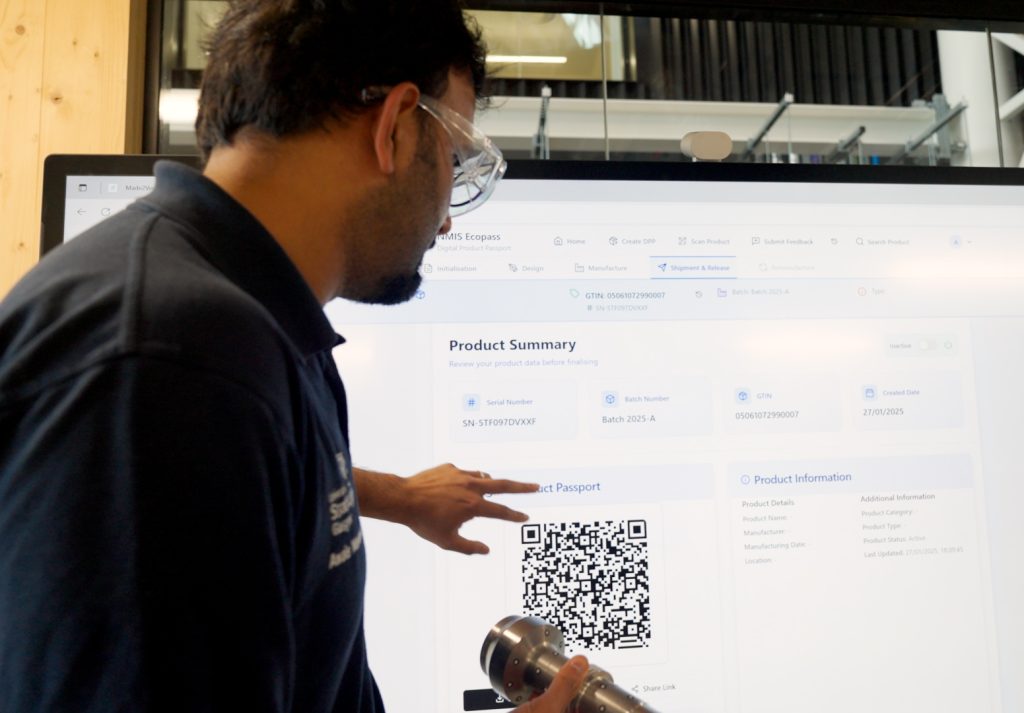

While a DPP is designed to provide full transparency on a product’s environmental footprint, from raw material extraction to end-of-life, it can also open up opportunities to develop novel business models. NMIS has been exploring the area for several years, as part of its ReMake programme, creating a bespoke data model focused on remanufacturing for high-integrity sectors – known as a ReMake DPP. The aim is to help businesses to capitalise on the opportunities that DPPs can bring, particularly in terms of sustainability, by optimising remanufacturing processes and enhancing product quality.

Capturing untapped value

Through a remanufacturing-focused ReMake DPP, manufacturers can build in intelligence along the product lifecycle, from design through to end of use. By embedding digital tools and data into every step, we can enable more efficient decisions about repair, reuse, and recovery while capturing untapped value.

Existing DPP implementations tend to focus on consumer-facing information for new products, but moving forward, they should also consider the opportunity for products already in circulation and the environmental impact of remanufacturing. The remanufacturing process requires granular technical data, including disassembly sequences, component material composition, and tracking of repair cycles.

Specific data can be included in a part’s ReMake DPP from the outset, such as information about the original materials and processes used, allowing them to be replicated to bring the part back to life after months or years in use. It could also provide a link back to the original manufacturer, enabling new opportunities for service-based business models, where users return the parts to the manufacturer for repair and remanufacturing long after the original purchase.

A DPP will also contain significant information about the carbon footprint of a component, further highlighting the case for remanufacturing and illustrating the lost value if the product is not put back into circulation.

Building the system

Research conducted by NMIS examining a range of EU DPP initiatives revealed a significant gap in data models specific to addressing circular economy needs.

Industry engagement and workshops further highlighted the requirements of ReMake DPP data, which, although fragmented, can be found in industrial business systems such as Enterprise Resource Planning (ERP), Product Lifecycle management (PLM), Manufacturing Execution Systems (MES), supply chain portals, and siloed systems.

However, for a DPP to work effectively, there must be a common model for communicating information. This is where NMIS’s ReMake DPP platform and open-source toolkit comes in, offering a way of identifying and mapping product data and generating a ReMake DPP, which meets the requirements.

Using this research, NMIS can support companies to pilot their own DPPs for remanufacturing, derisk investment, and open up global supply chain opportunities to showcase the impact of high-value remanufactured products. We have also developed tooling to enable companies to prototype a DPP using their data and a foundational test bed to show how data can flow between the remanufacturer of the product and the original equipment manufacturer.

An example: Deploying Digital Product Passports to unlock new circular opportunities

Over the past two years, NMIS has worked with companies from aerospace, electronics, textiles and industrial equipment to develop and deploy Digital Product Passport solutions. One flagship research project focused on compressor remanufacture and repair, combining technical innovation with a service-based business model to drive circular value.

In this project, advanced reconditioning processes were used to return worn compressor screw rotors – critical in aerospace, energy, maritime and industrial applications – to as-new condition rather than replacing entire machines. Remanufacturing using cold spray coating instead of traditional electro hard chrome (EHC) delivered improved performance while avoiding environmental and health and safety risks.

Alongside the technical solution, the compressor company is now deploying a DPP into its enterprise resource planning (ERP) system. The DPP captures detailed component data including materials, processes and lifecycle history. This both supports future compliance requirements and enables the business to get closer to its customers and supply chain, secure repeat business, monetise data through the sale of approved spare parts, and retain detailed repair data for when the product returns for further work. Over time, this intelligence can also inform improved product design.

An economic and environmental opportunity

Going forward, we need to think about manufacturing differently. Currently, remanufacturing accounts for less than 2% of global material flows, highlighting the scale of the opportunity for change.

While digital product passports are key to making this transition, they also present significant opportunities for businesses. By embedding circular principles from the outset, we can dramatically extend product life, reduce reliance on virgin materials, and cut emissions, but also enable resilience, cost savings, and new revenue streams that focus on maximising product value.

The environmental benefits are clear, but it is also a chance for the UK’s manufacturing sector to get ahead of the curve, adapting business models, monetising data and upskilling to meet the challenge. By working together, we could see new businesses and supply chains formed, while keeping more products in circulation for longer.

NMIS is operated by the University of Strathclyde and part of the High Value Manufacturing (HVM) Catapult.

For more articles like this, visit our Digital Transformation channel.